OptoSphere

Prosthesis head measurement machine for artificial hip joint implants

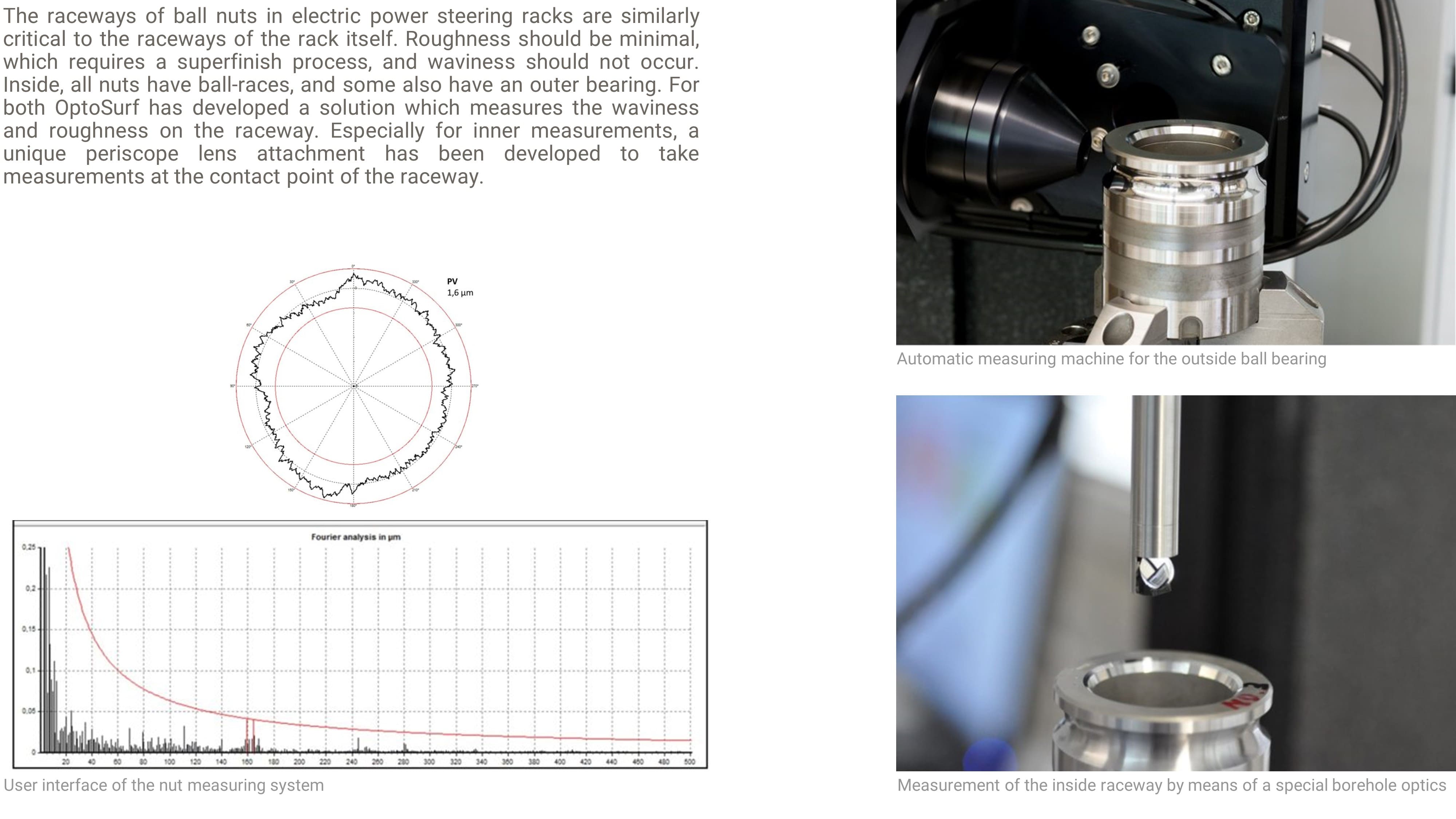

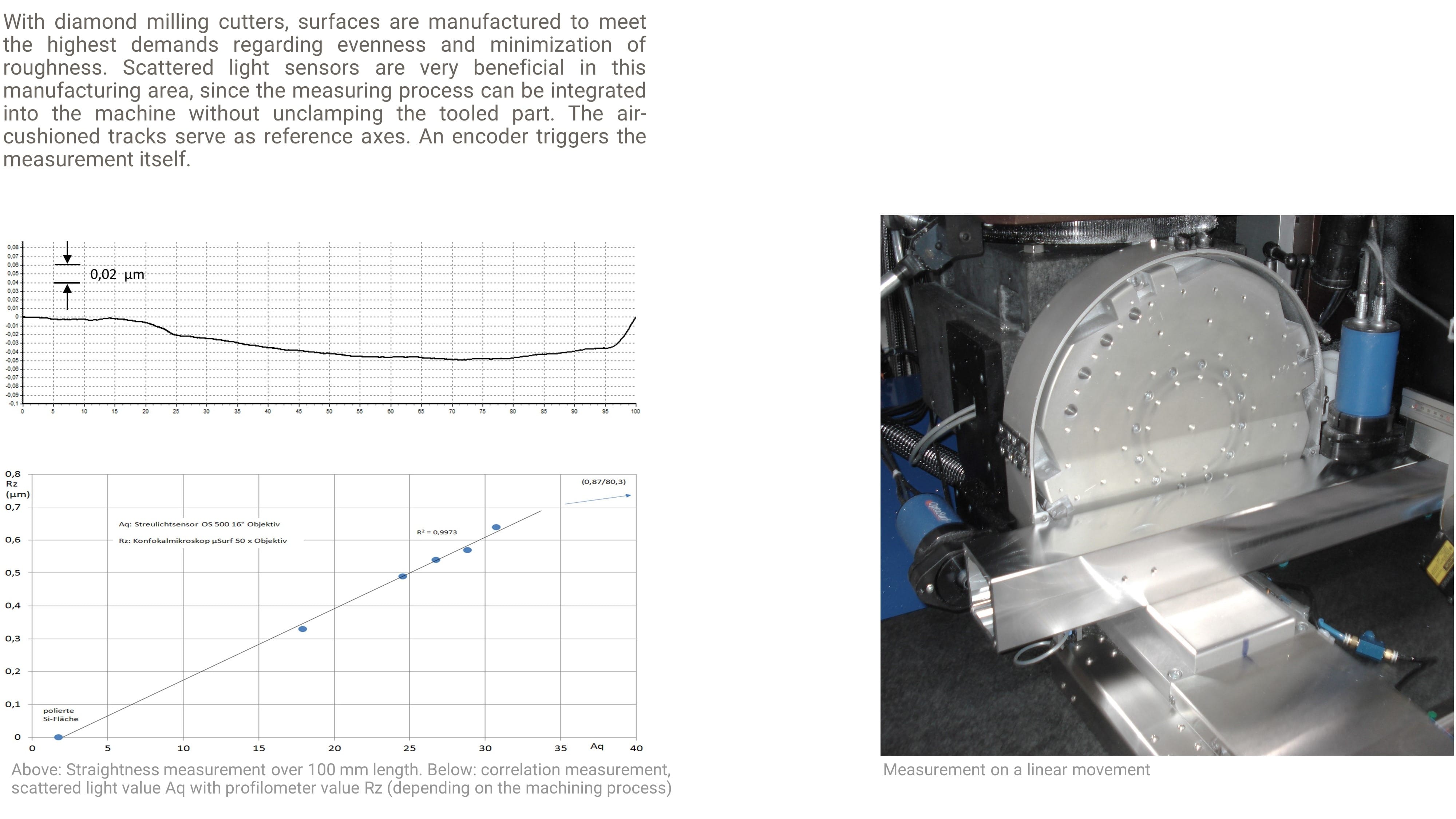

Even today, full surface inspection of artificial hip joint implants is often still performed with the human eye. However, the OptoSphere measurement device for artificial hip joint prosthesis heads is clearly superior to a visual inspection. In one single measuring cycle, Aq (roughness), defects and form deviations are measured dependably and repeatably. The measuring device has been developed especially for prosthesis heads made from metals or ceramics. The surface of the polished spheres need to meet the highest standards and must be free of any kind of damage such as scratches or stains.

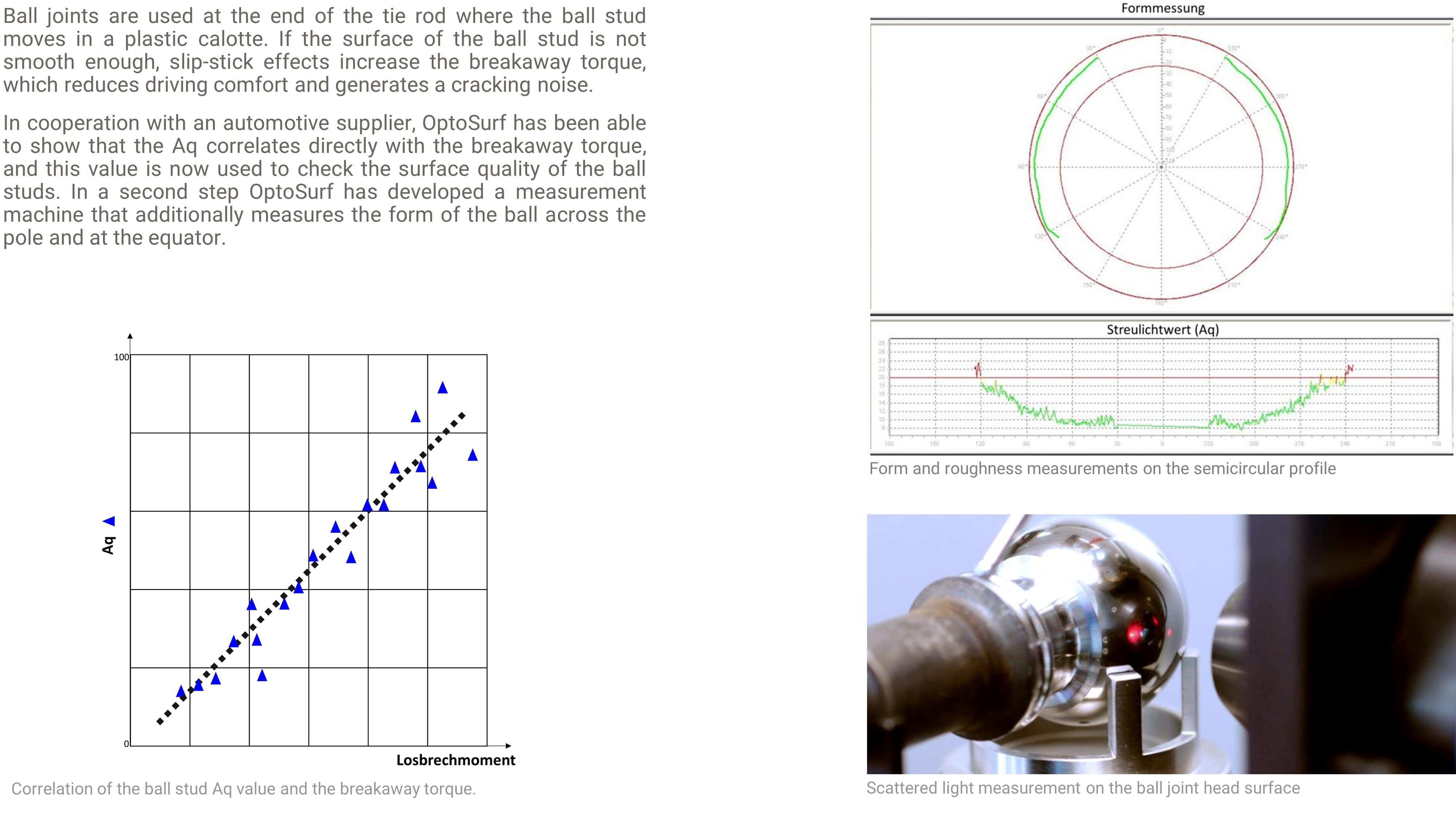

To perform the measurement, the ball surface is scanned by the sensor, which is swiveled while a rotary table rotates the implant. The defect detection software can detect scratches of as little as 0.1 µm in depth.

In a second measurement, the dimensional accuracy is determined, which is supposed to be < 0.5 µm at the equator and below » 1 µm at the pole. Optionally an additional tactile stylus (resting ball) can be used for measuring the diameter.