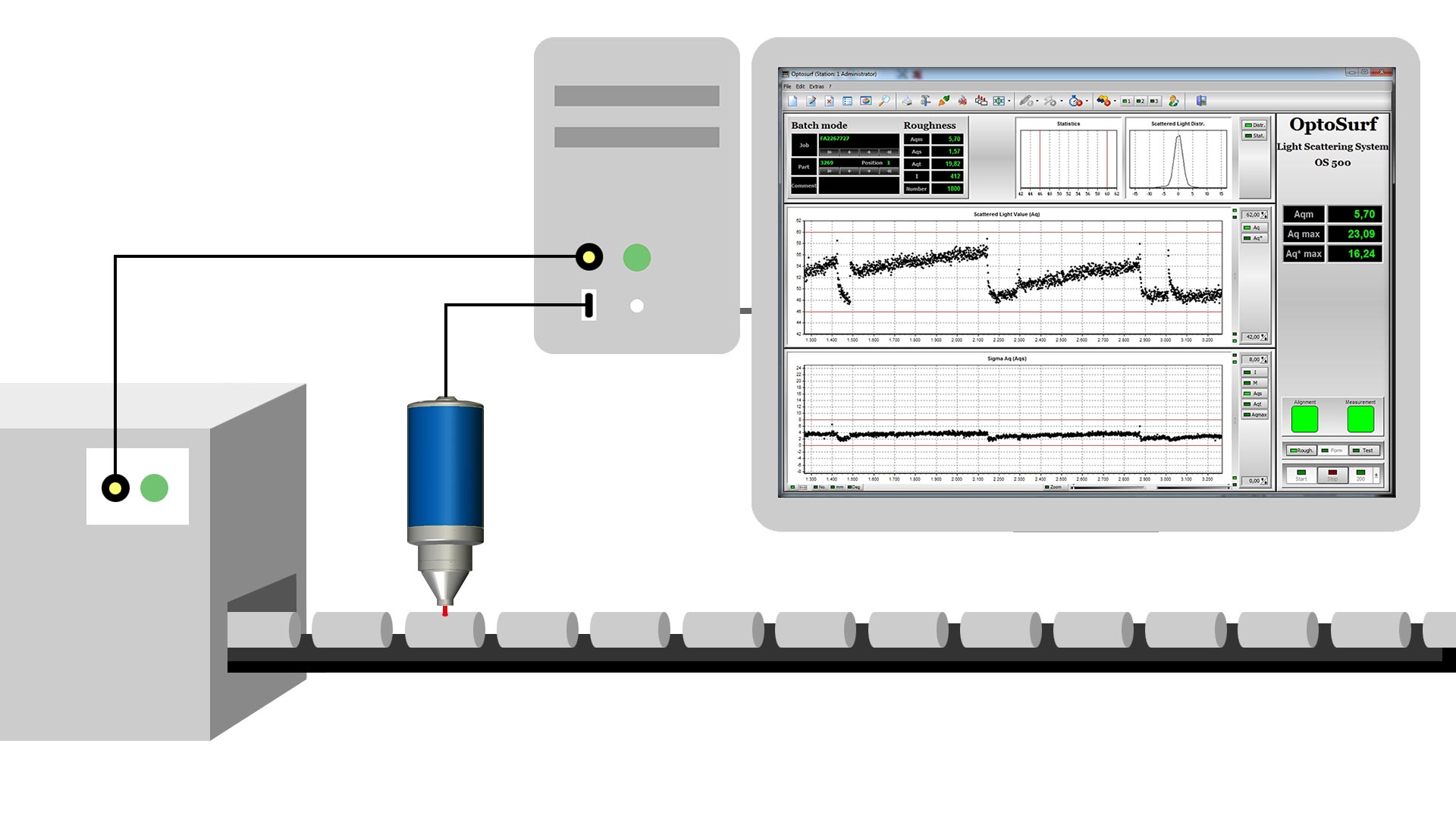

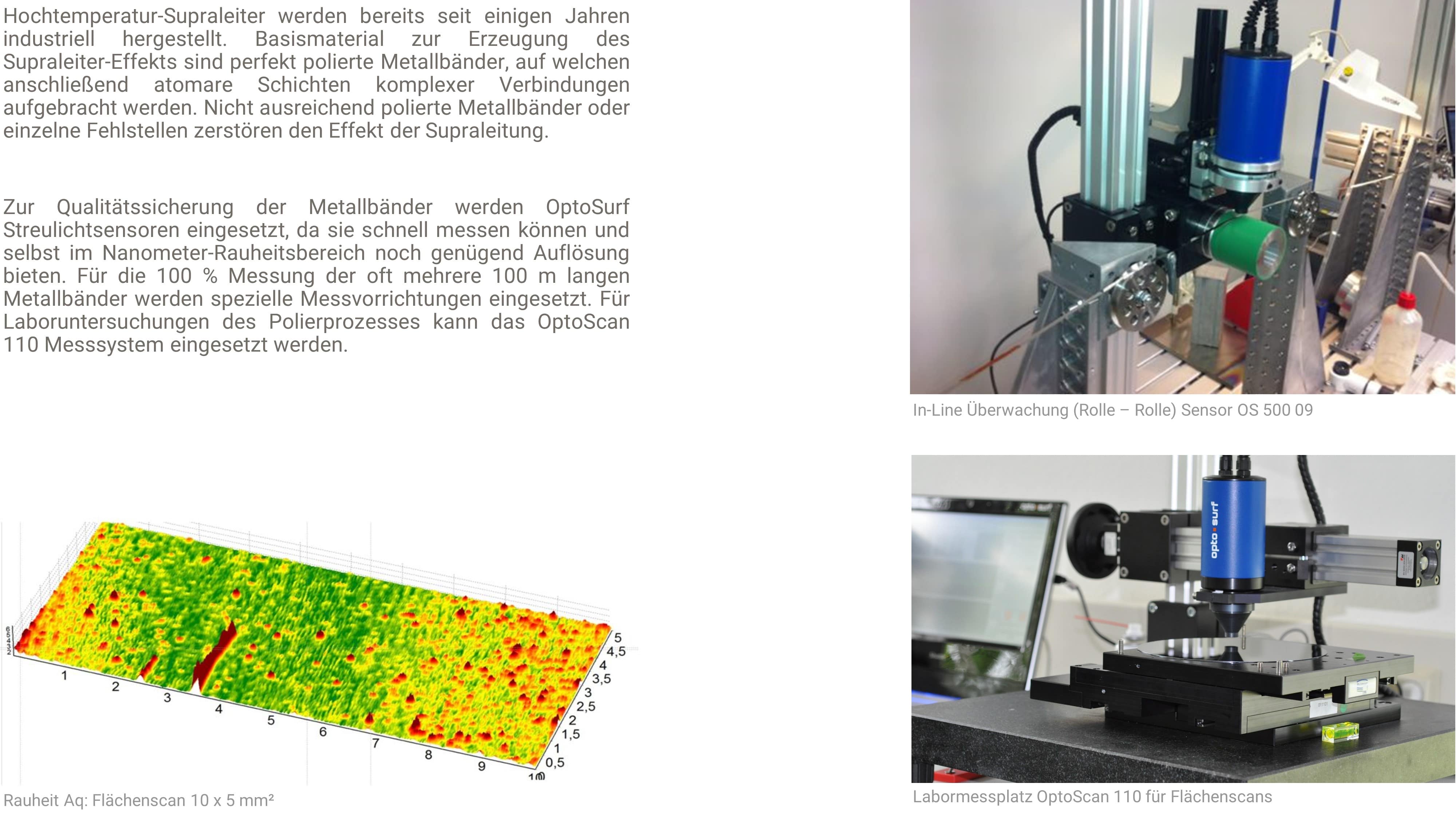

Inline sensor system OS500

Measurements – directly in the production line

Occurring ambient vibrations, temperature differences and reduced cycle times – those factors increase difficulties for using conventional measurement devices like tactile roughness testers, confocal microscopes or KMGs for inline quality assurance and process control. In opposition scattered light sensors are insensitive to influence from the harsh production environment.