OptoShaft

Shaft measurement device

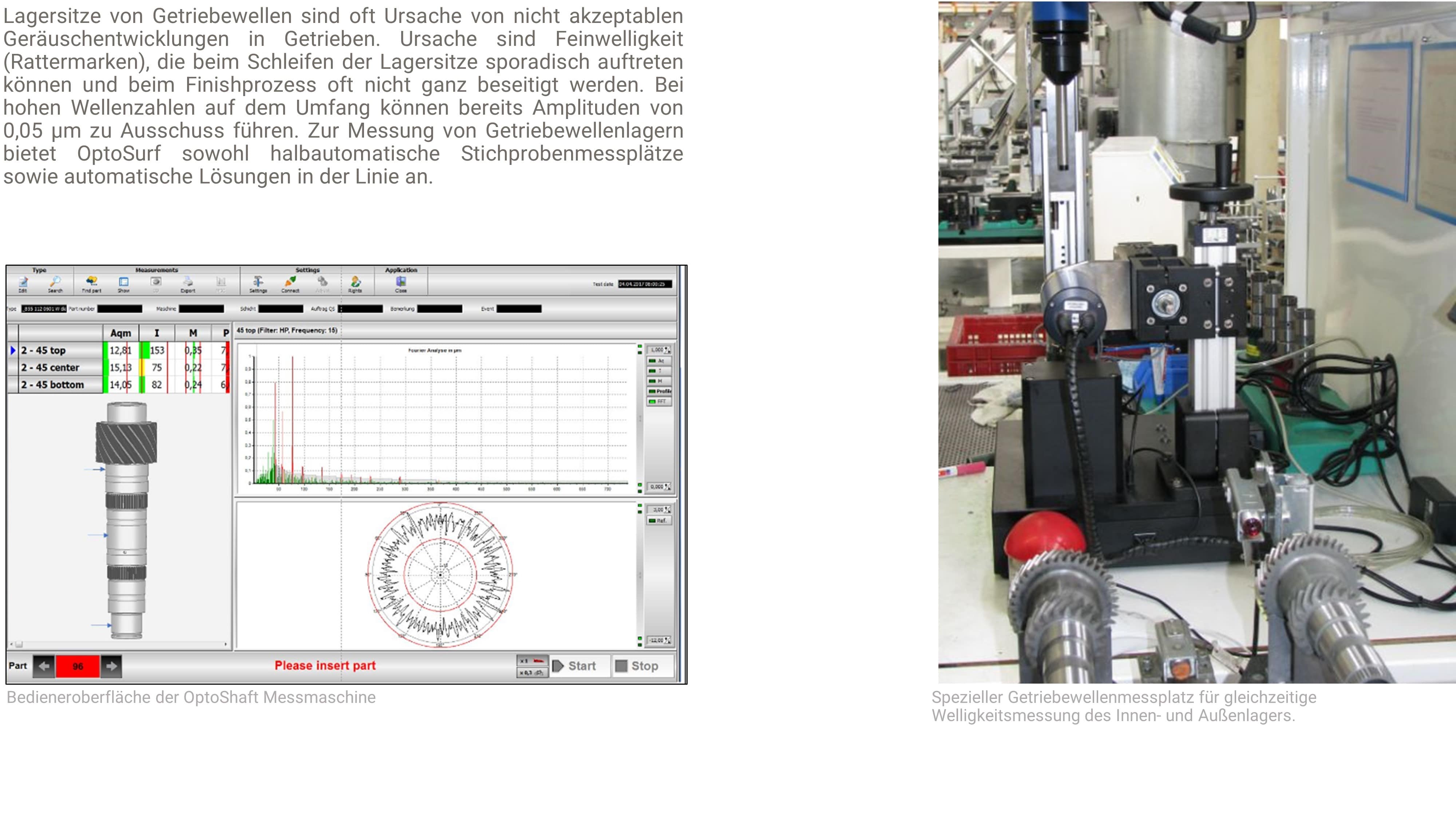

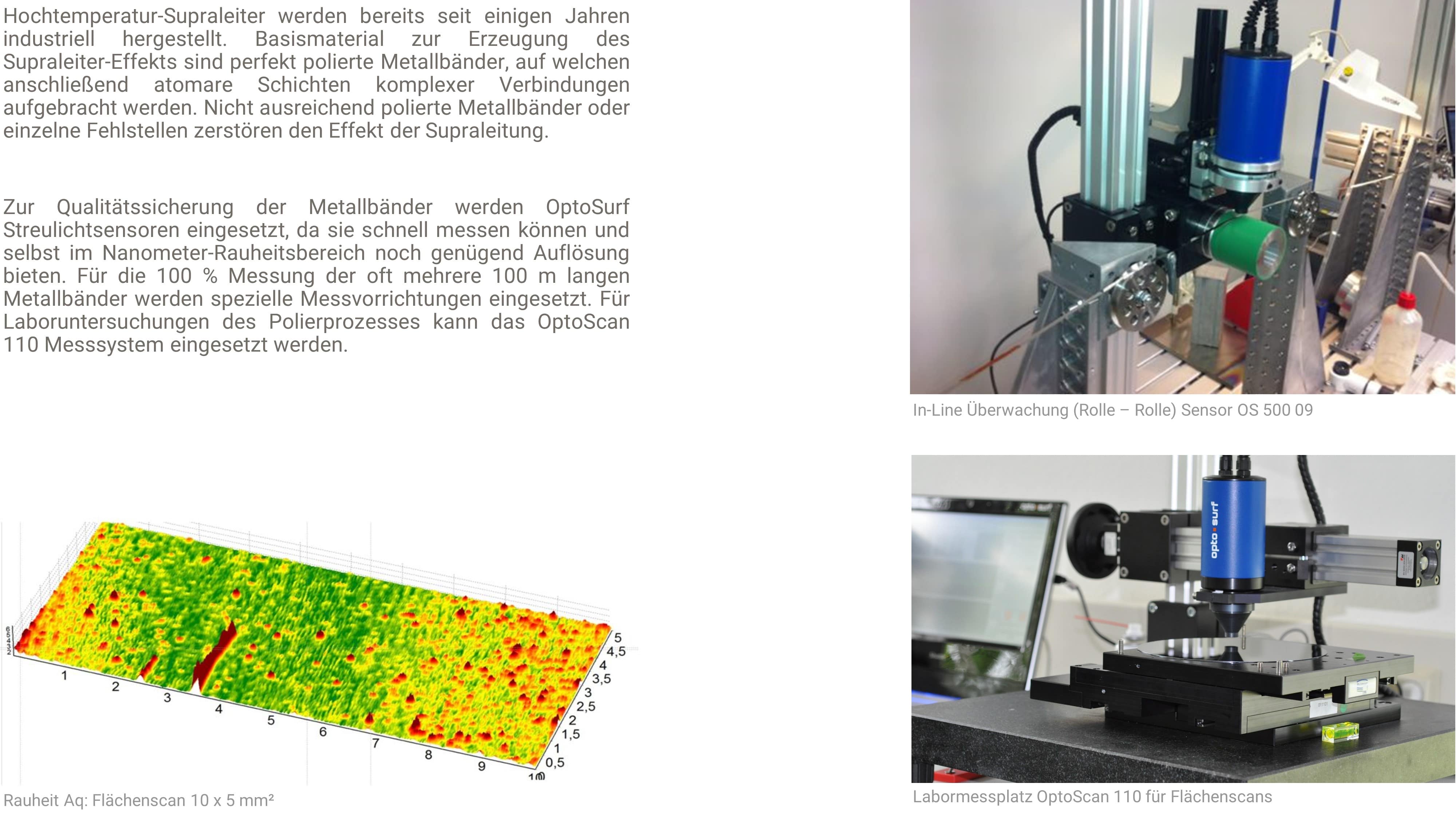

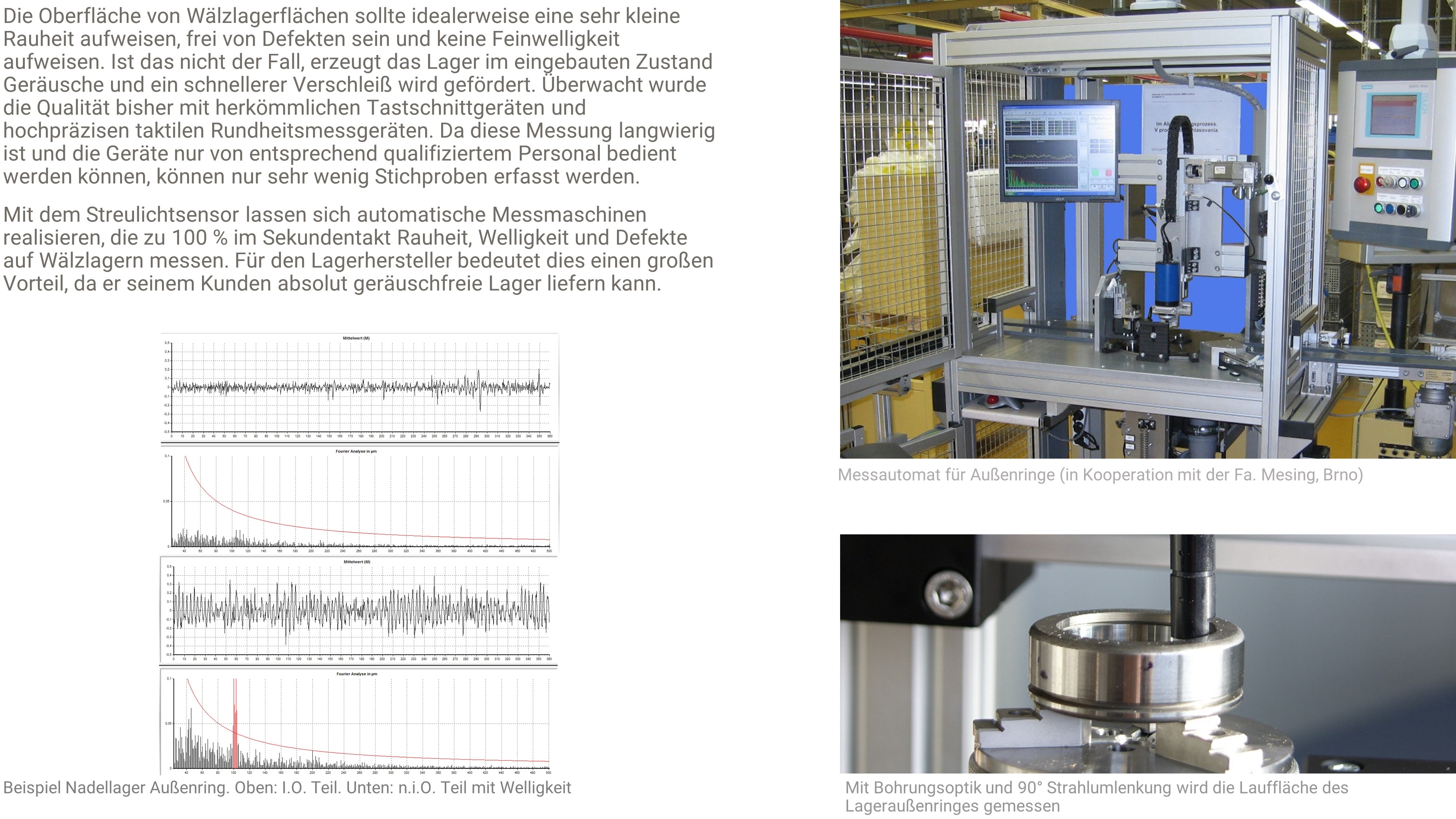

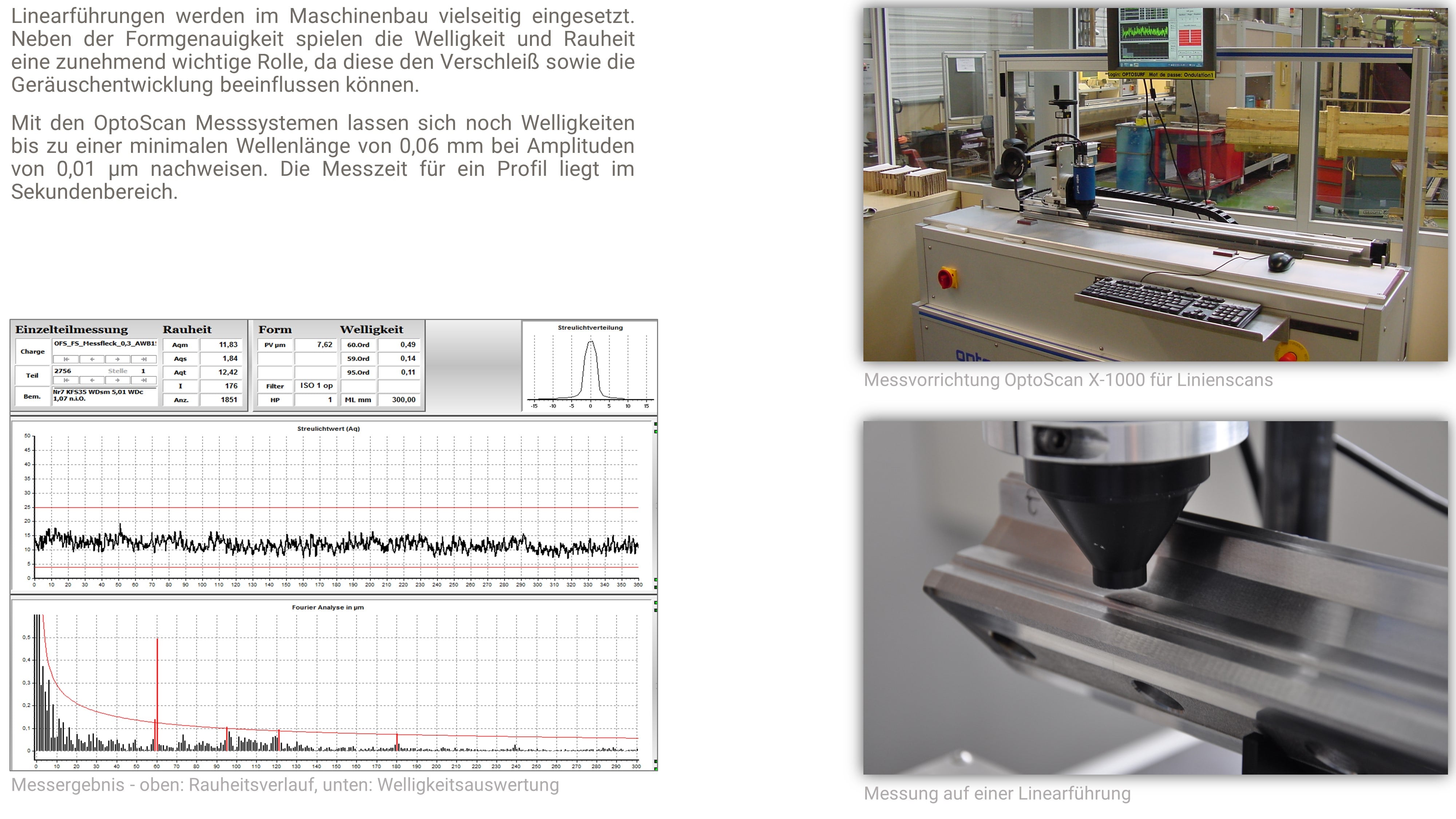

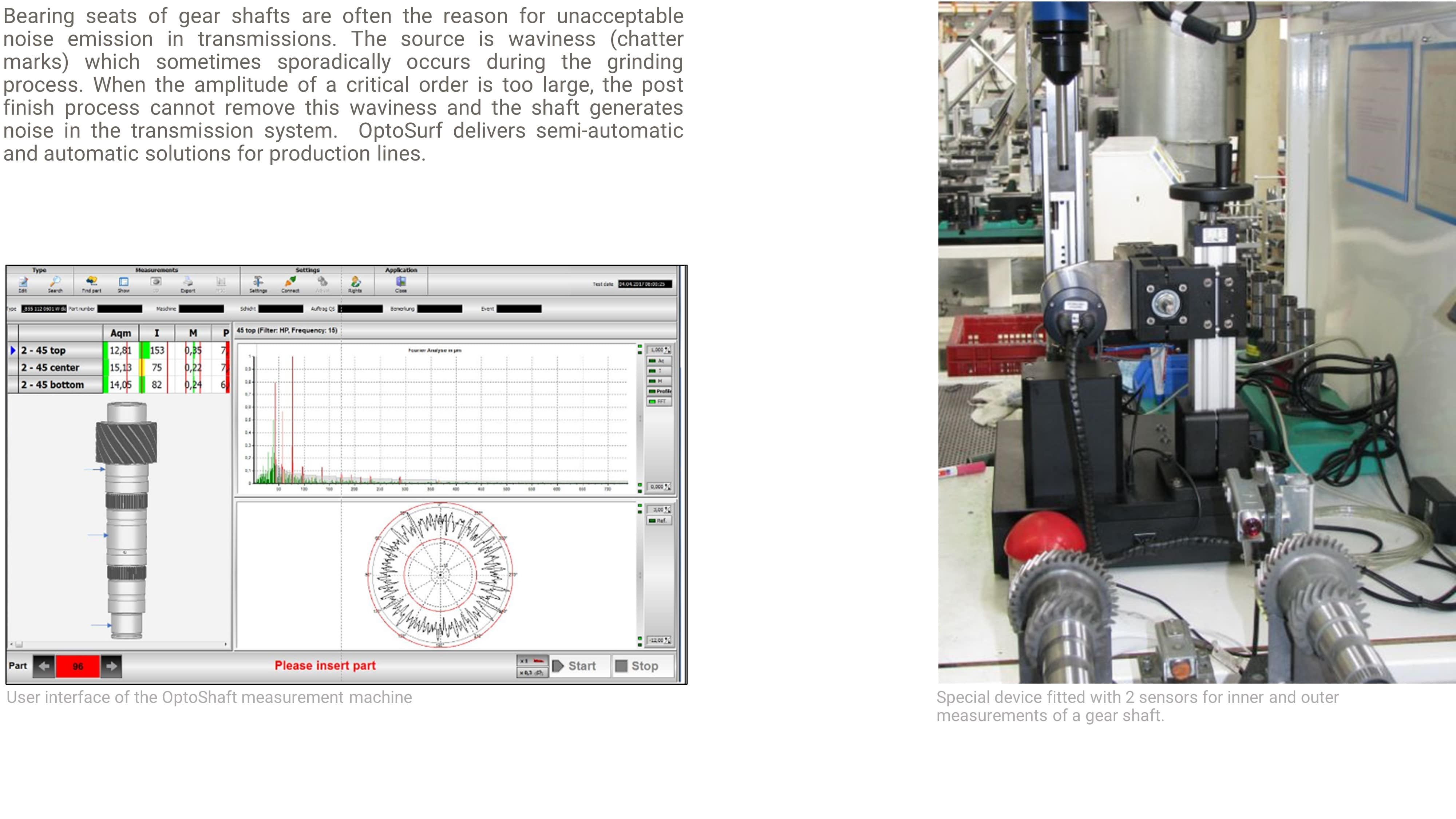

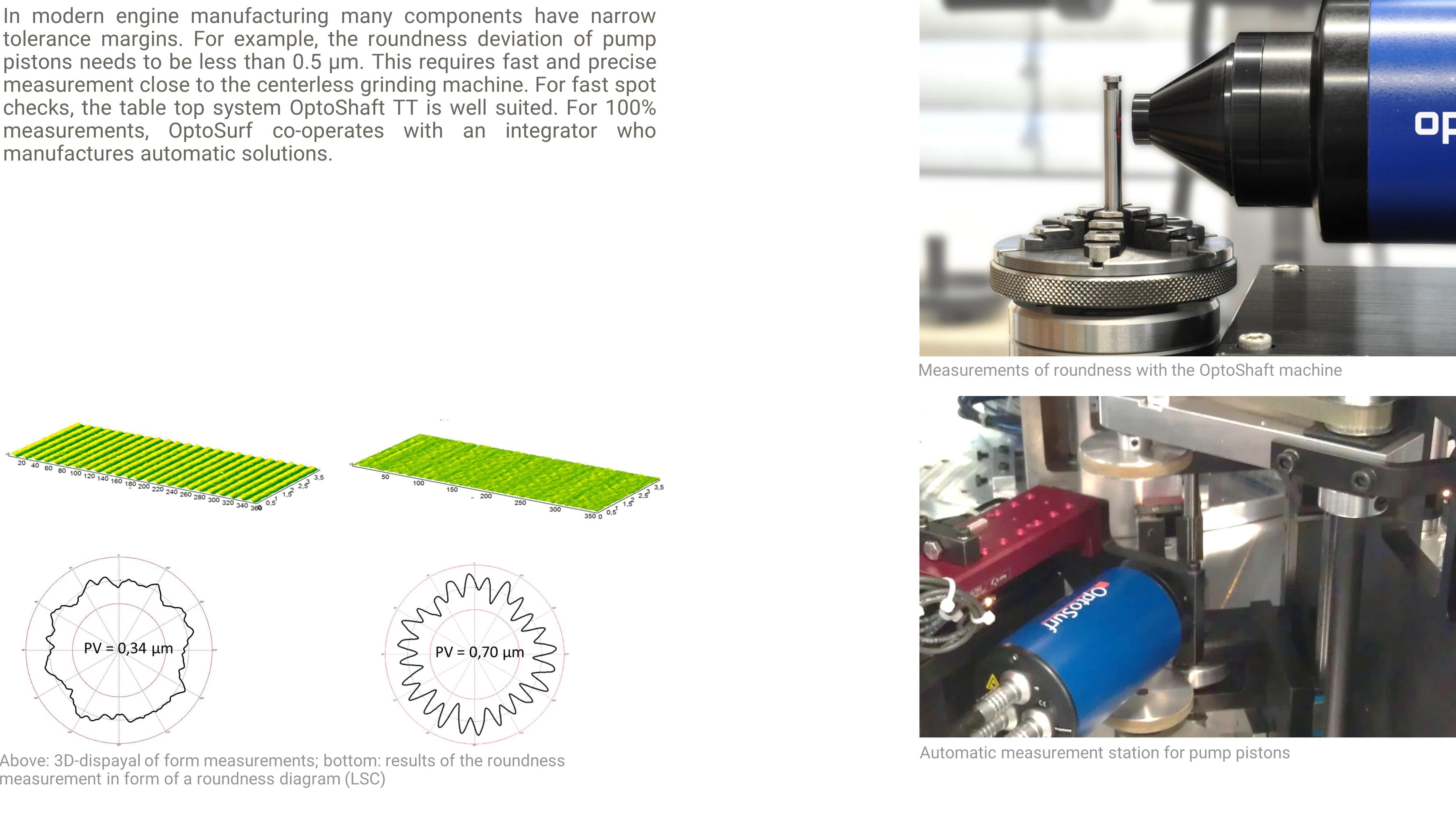

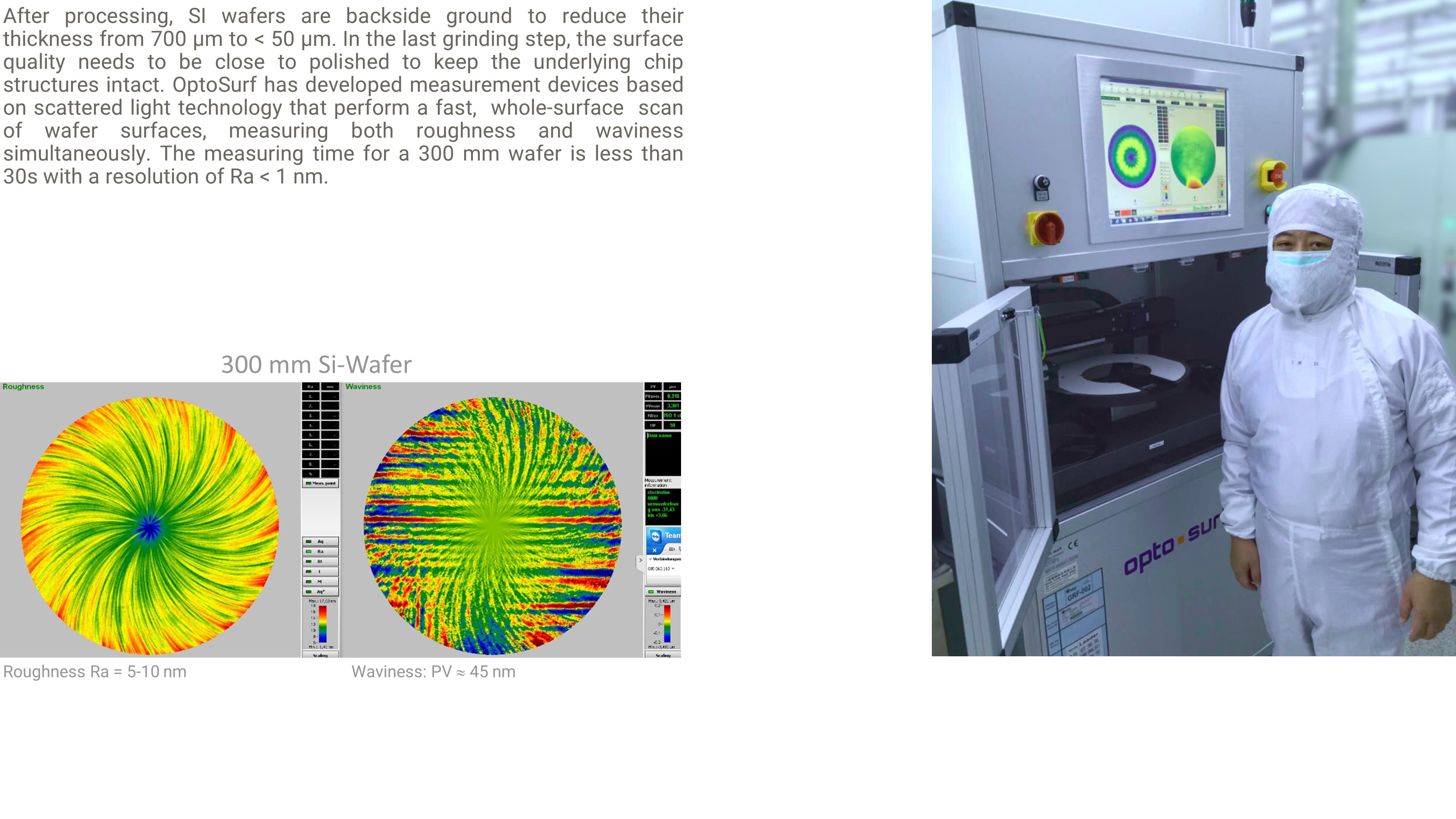

Shafts are installed in almost every type of vehicle. These parts are highly critical in view of the growing demands with regard to efficiency, lifetime and noise emission. Especially critical are finished running surfaces used as rotating needle bearings. Even small waviness with amplitudes < 0.05 µm can generate noise emissions that are not tolerable. The reason for waviness is chatter marks on the running surface which occur during grinding and are not totally removed from the running surface by the finishing process. These NOK parts are often only identified much later when noise tests are performed. In case of unacceptable noise emissions, the shaft needs to be demounted from the transmission, resulting in high reject costs. The necessary testing procedure is then very expensive since many produced parts will subsequently be tested in separate testing rooms.

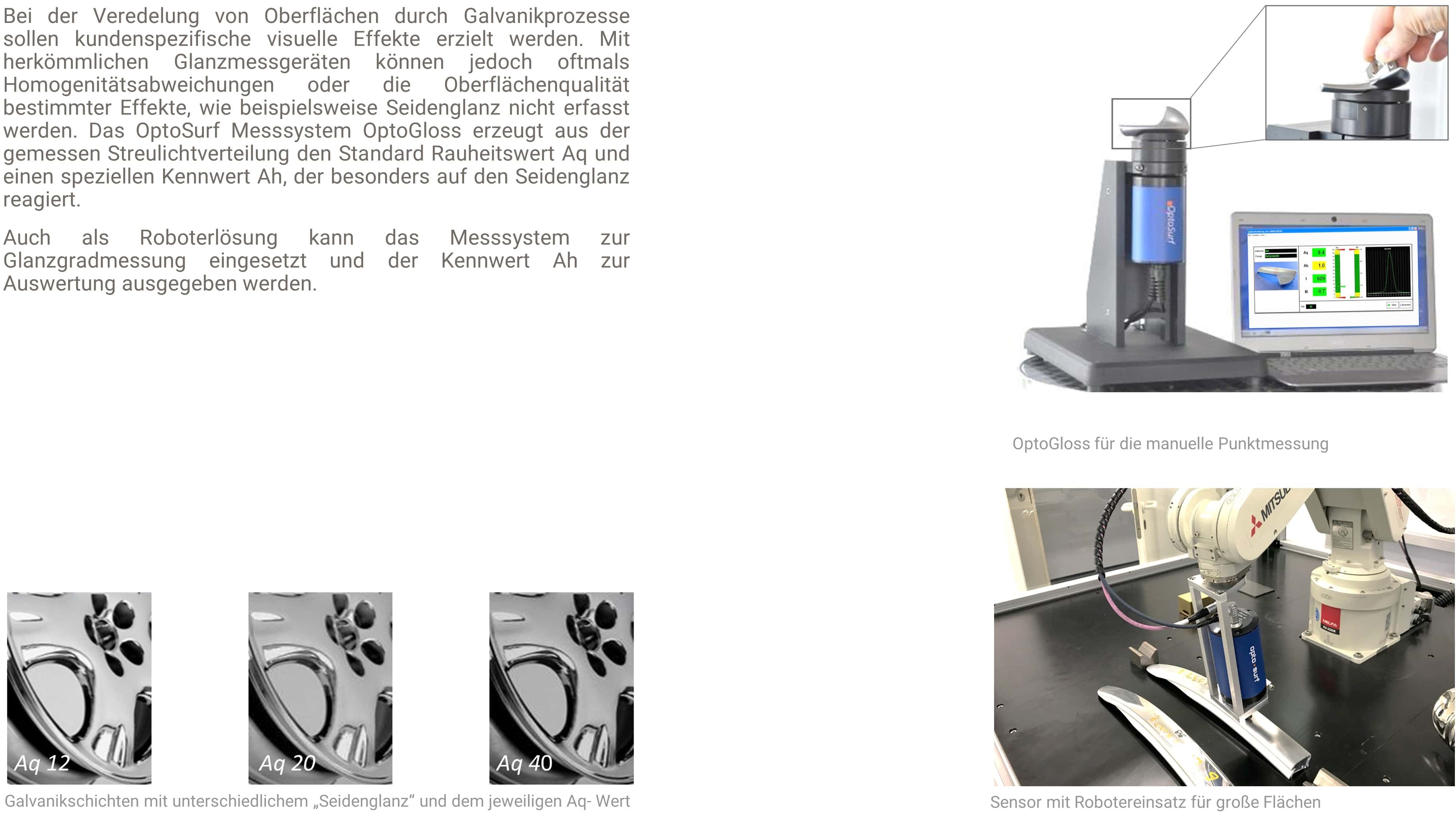

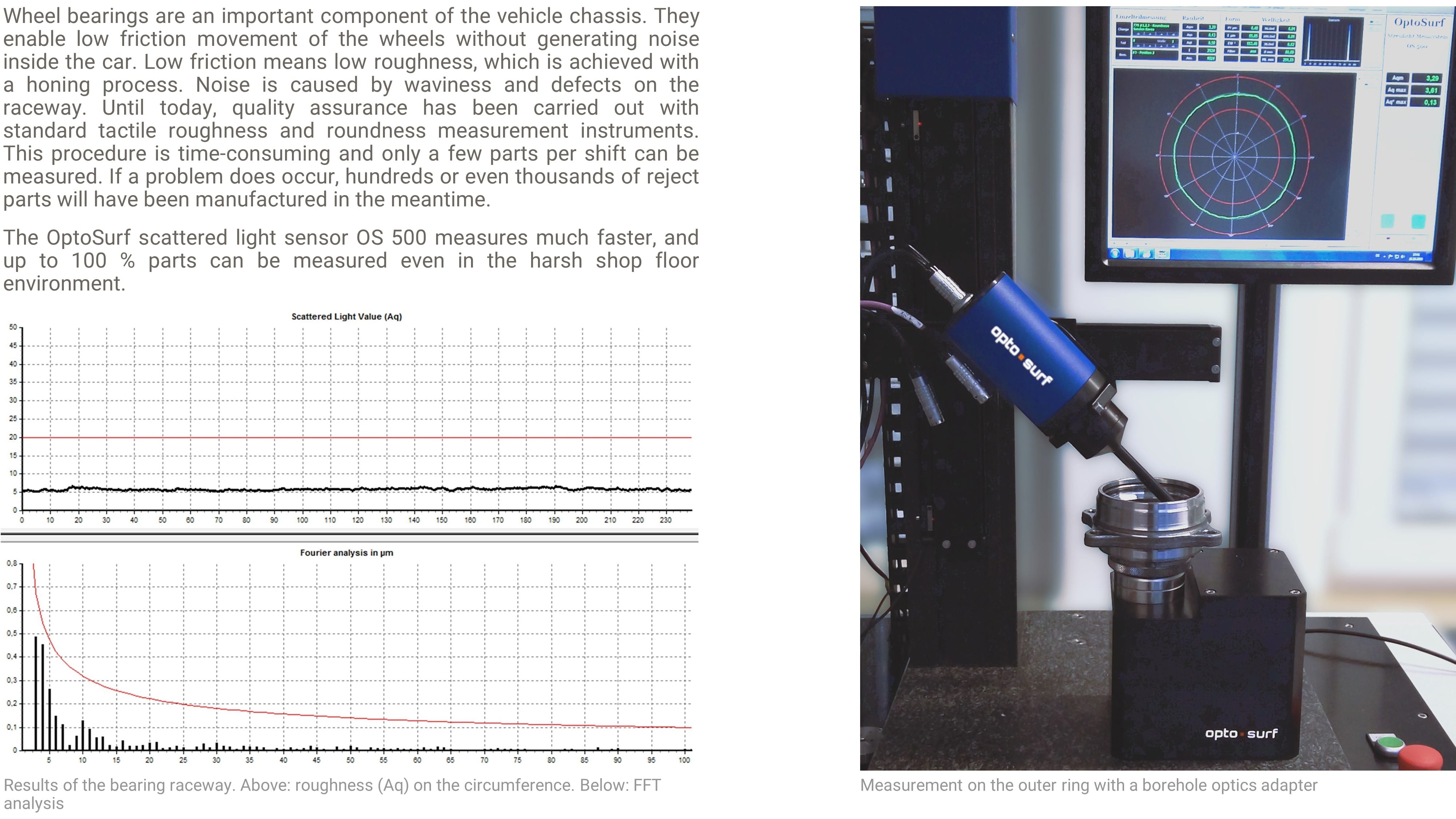

The OptoShaft measuring device can easily be operated by a worker, and can completely replace time-consuming tactile measuring devices. It is possible to integrate automated inline measurement solutions into the production process.