OptoScan

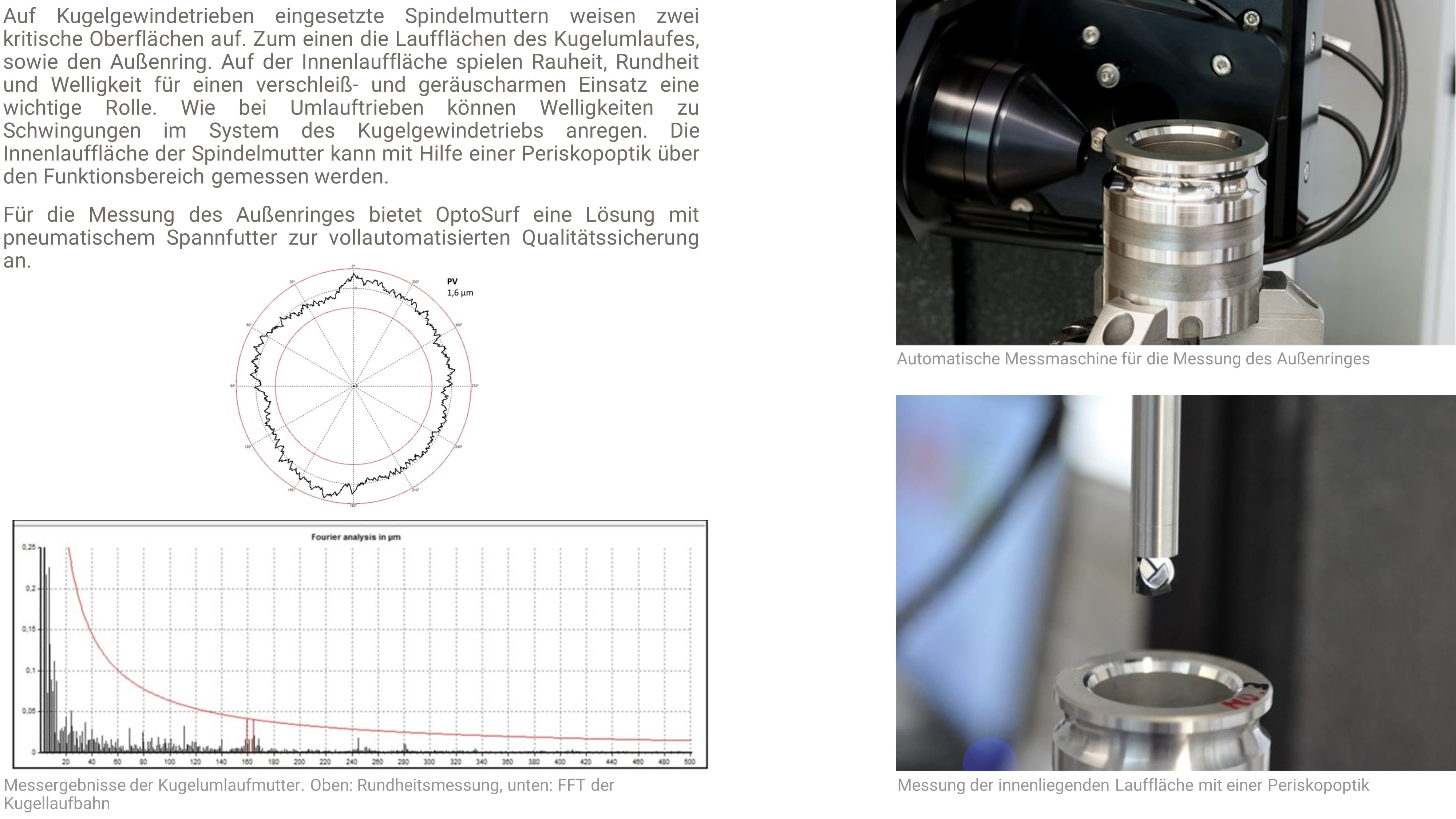

x-y-measuring table system

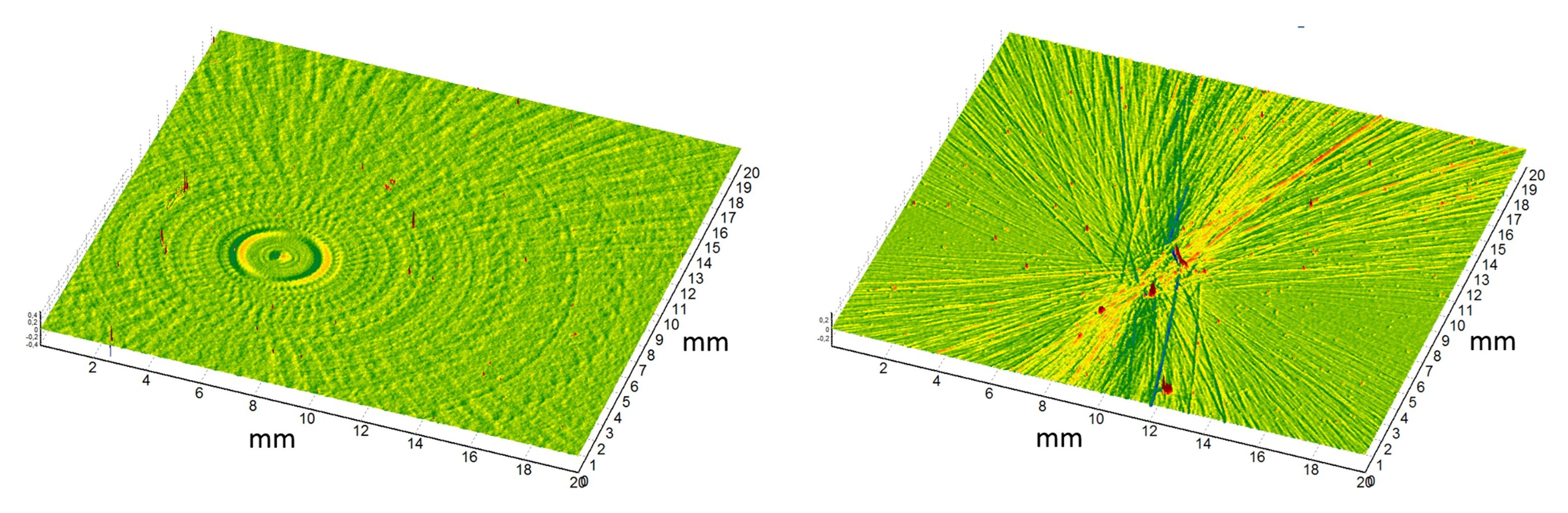

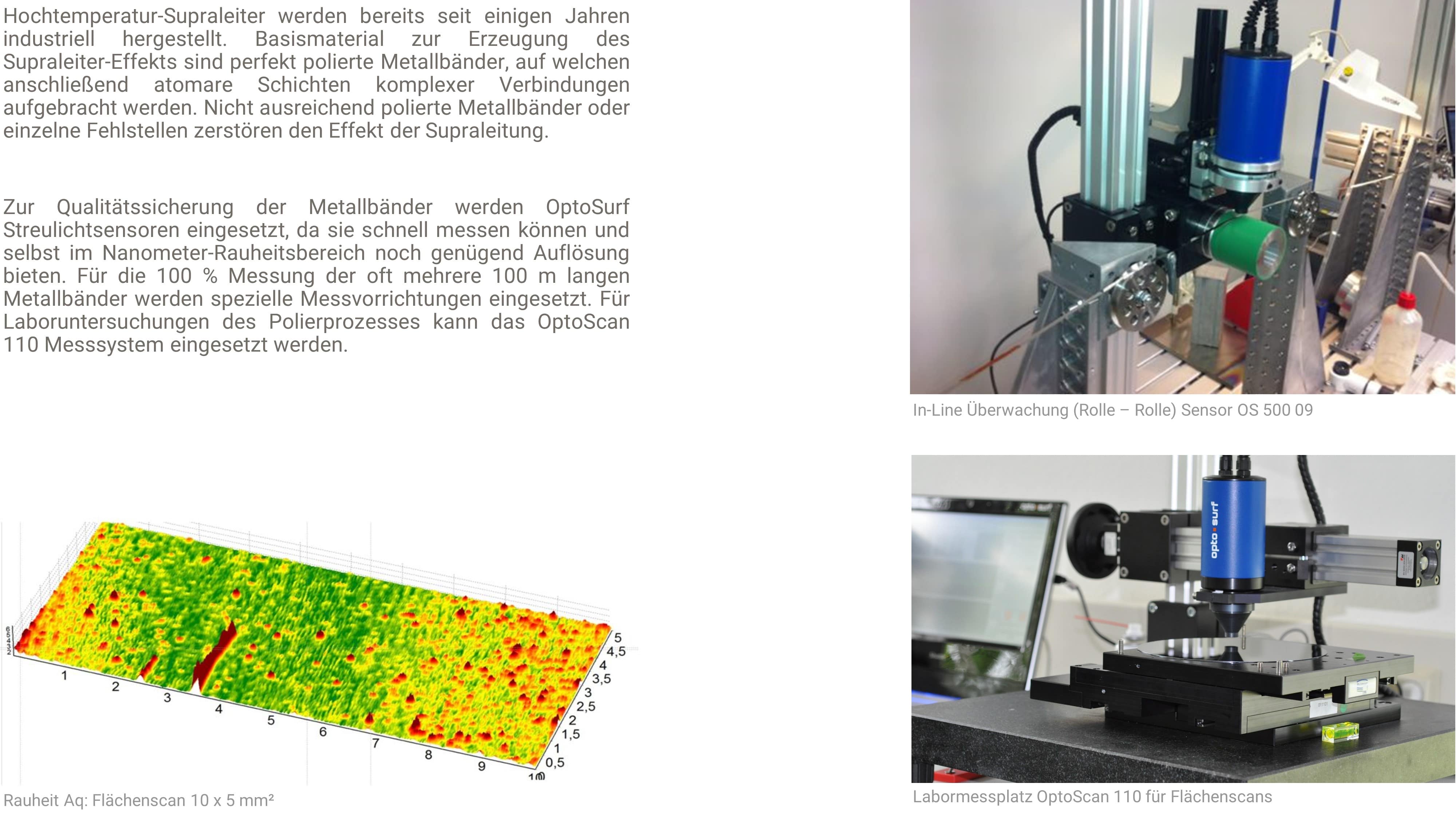

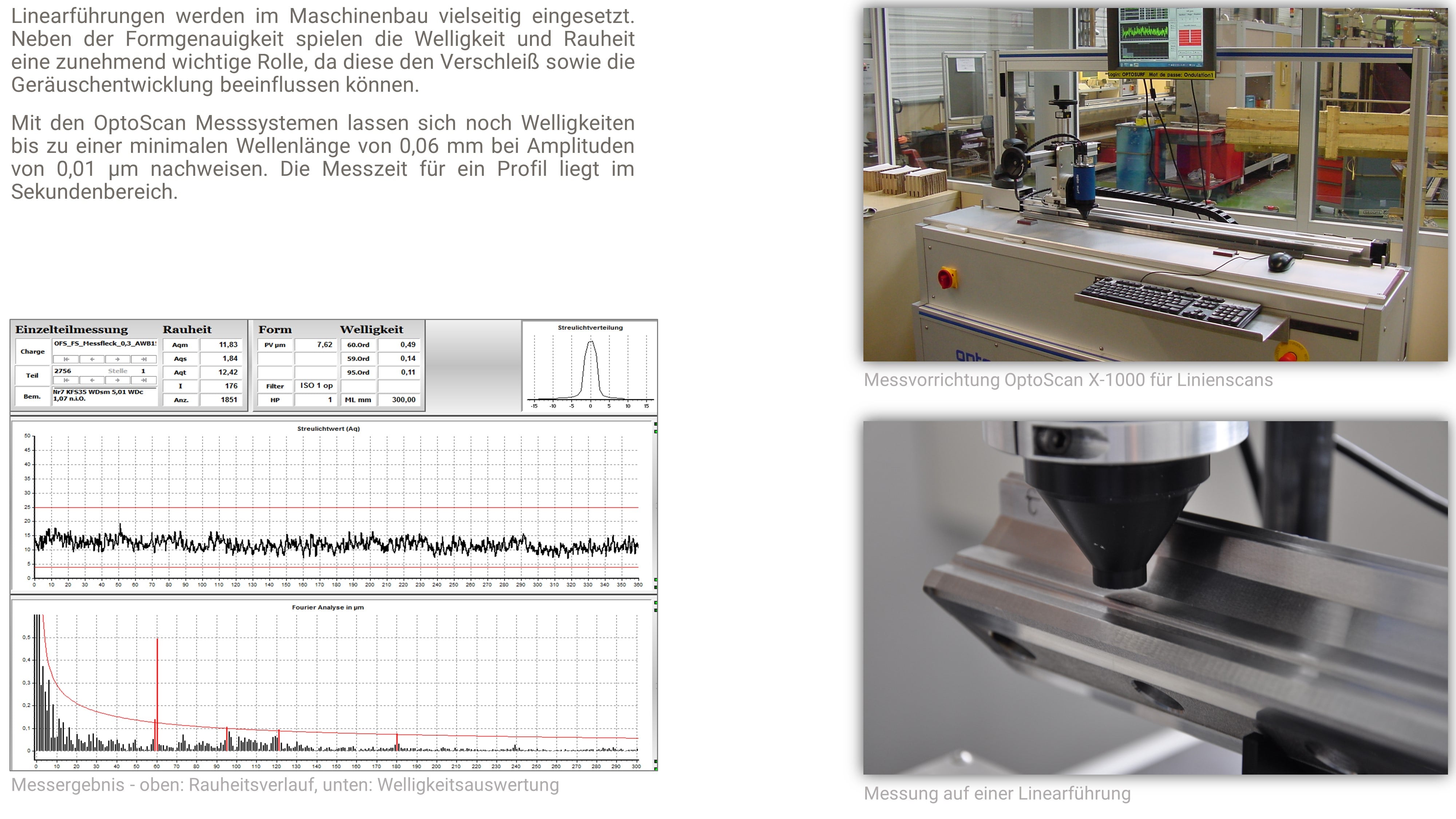

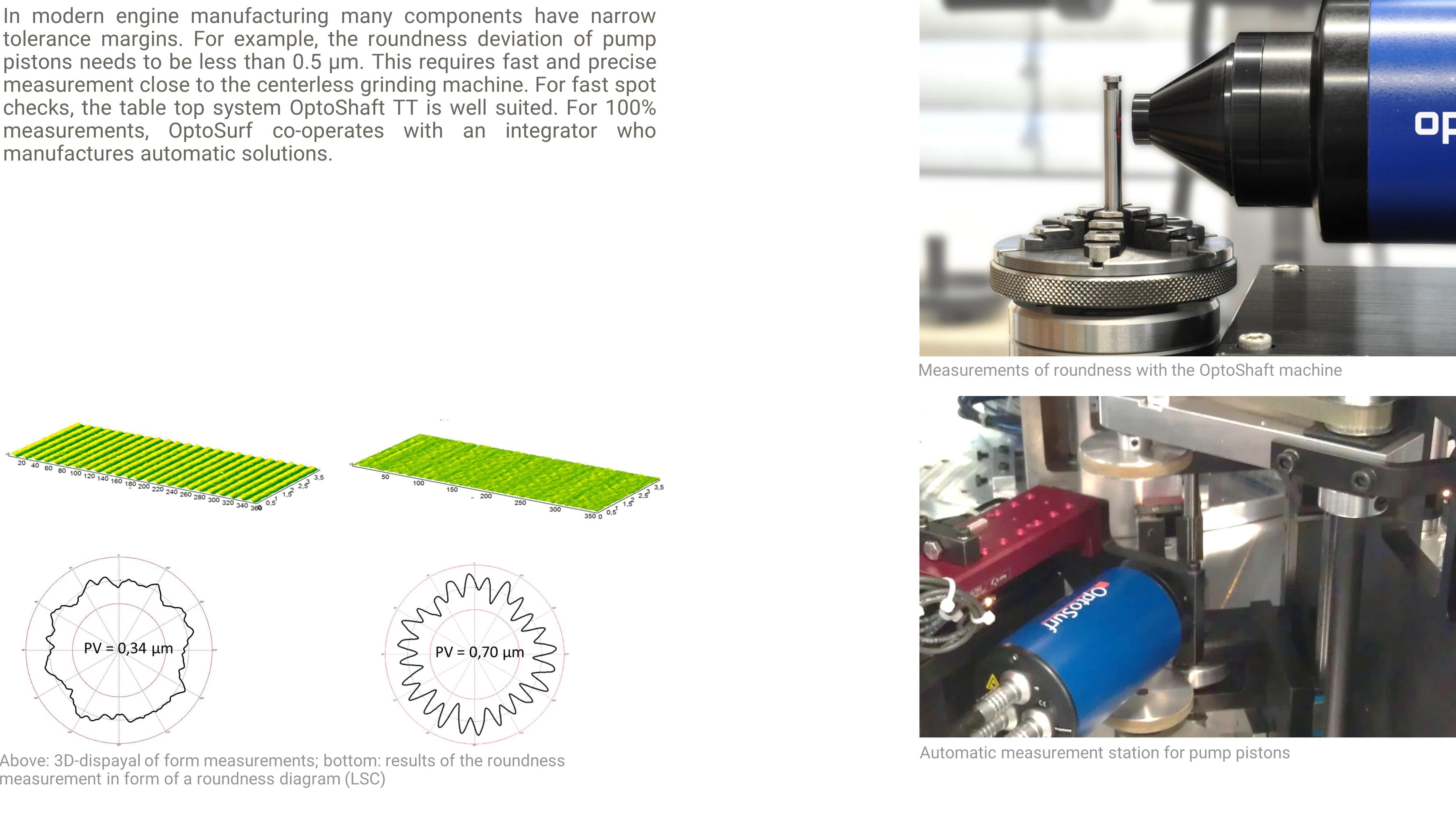

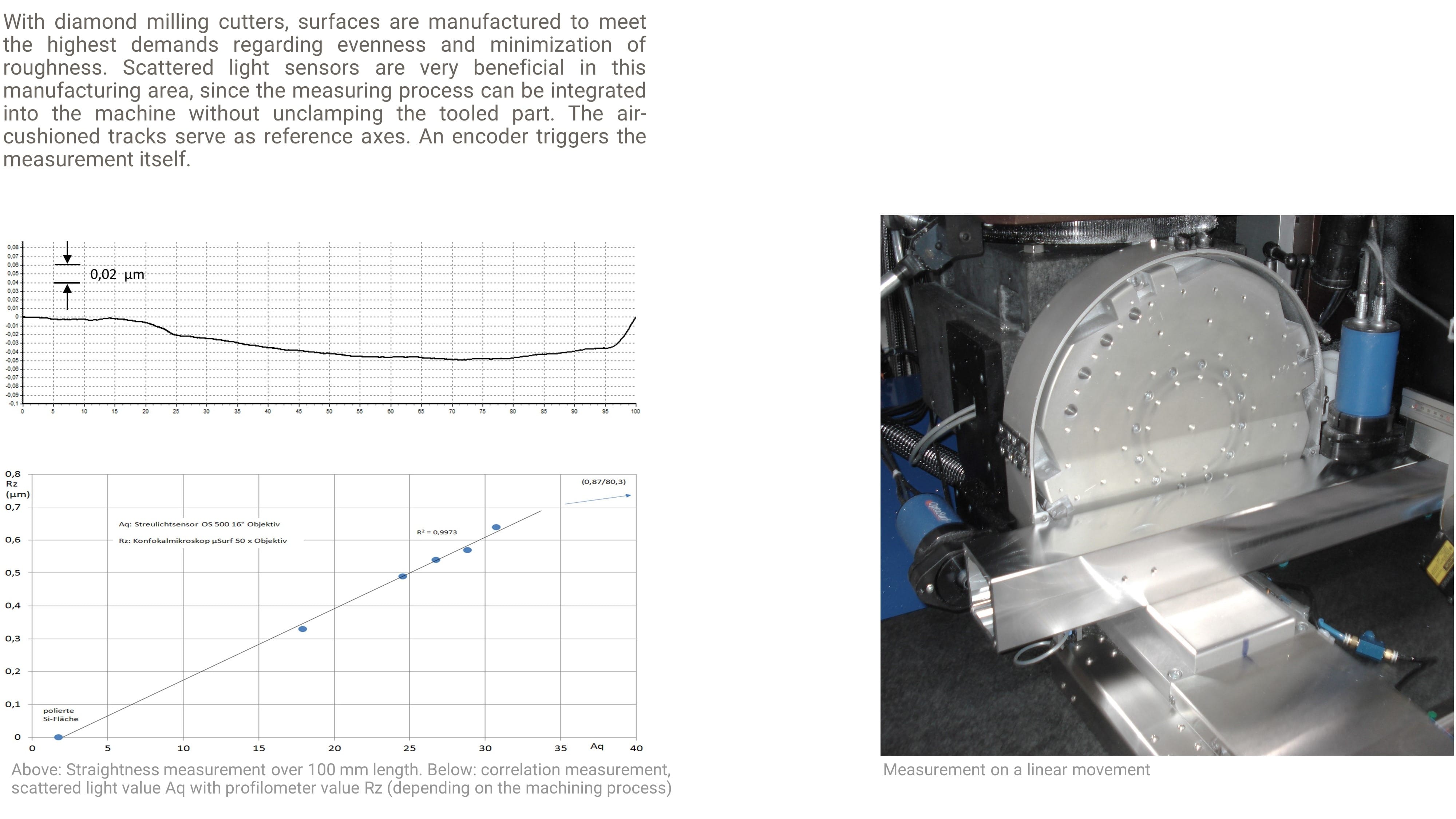

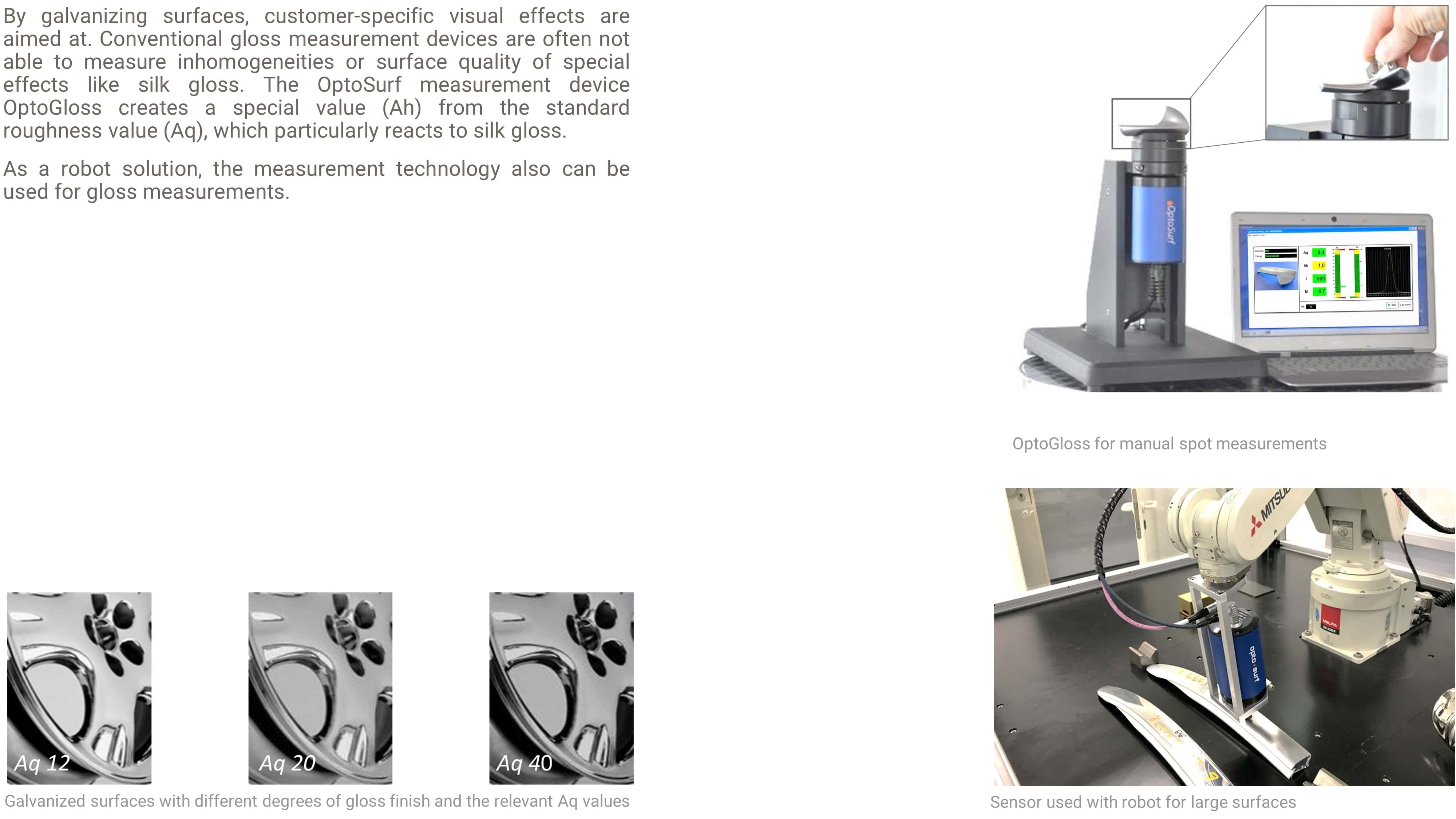

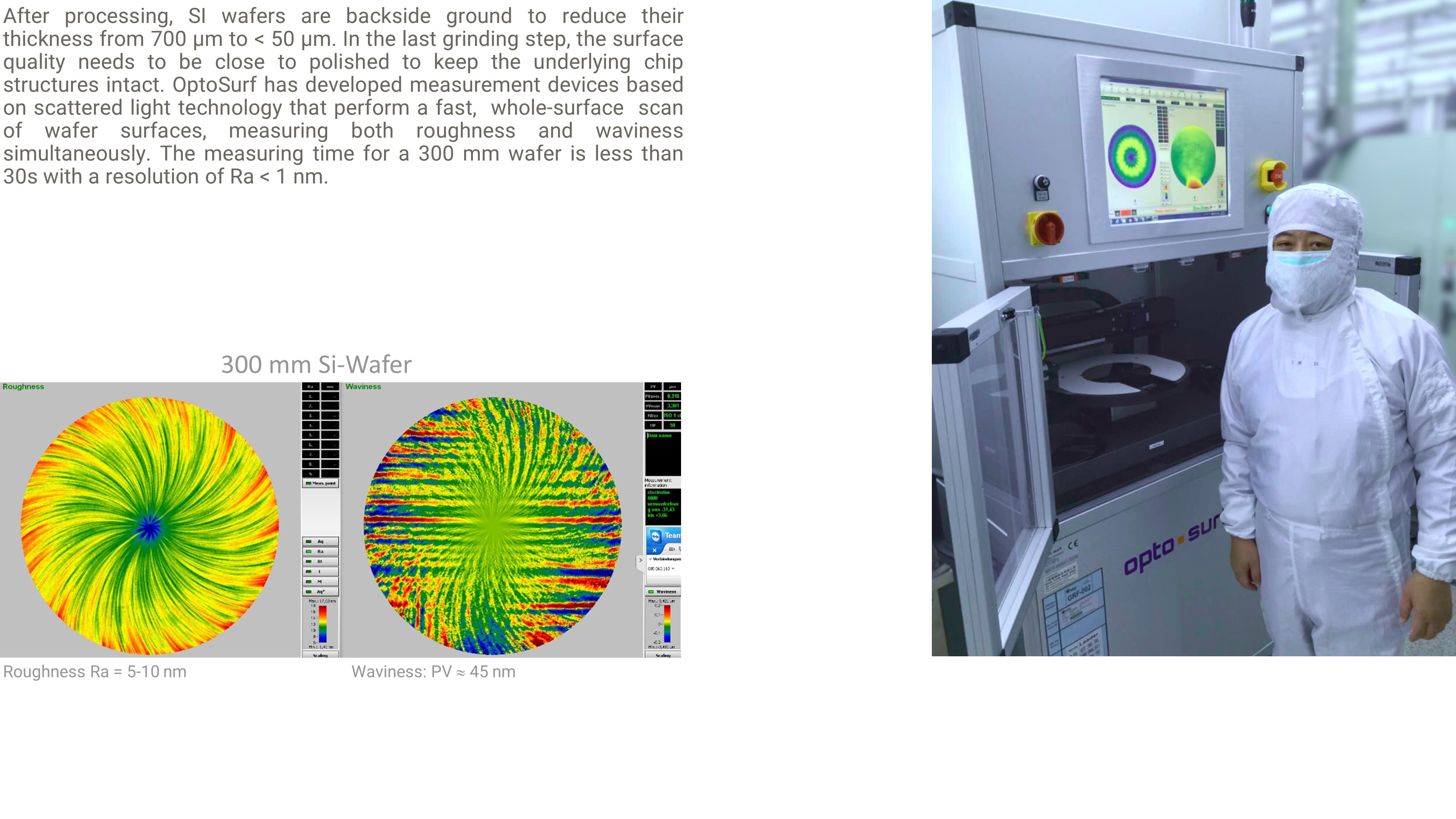

The x-y measuring table system OptoScan is ideally suitable for full scan measurements of flat measuring probes. Its main applications can be found in texture analysis, waviness measurement, gloss measurement, and defect detection. Thanks to the combination of a high-precision positioning system and the OS 500 scattered light sensor, form deviations even in the nanometer range are detected reliably. The table is controlled comfortably with the OptoSurf software. To visualize the detected data, 3D software instantly merges the collected data.

The maximum size for probes is 110 x 100 mm with the standard machine. The high-precision axes are driven by a linear actuator and provide measuring speeds up to 500 mm/sec. Thanks to a relatively high insensitivity to changes in measuring distance, even small mechanical imprecisions do not affect the precision of the system. Form deviations of < 0.1 µm are detectable over measurement lengths of 100 mm. The measuring range for roughness and waviness is 1 nm.