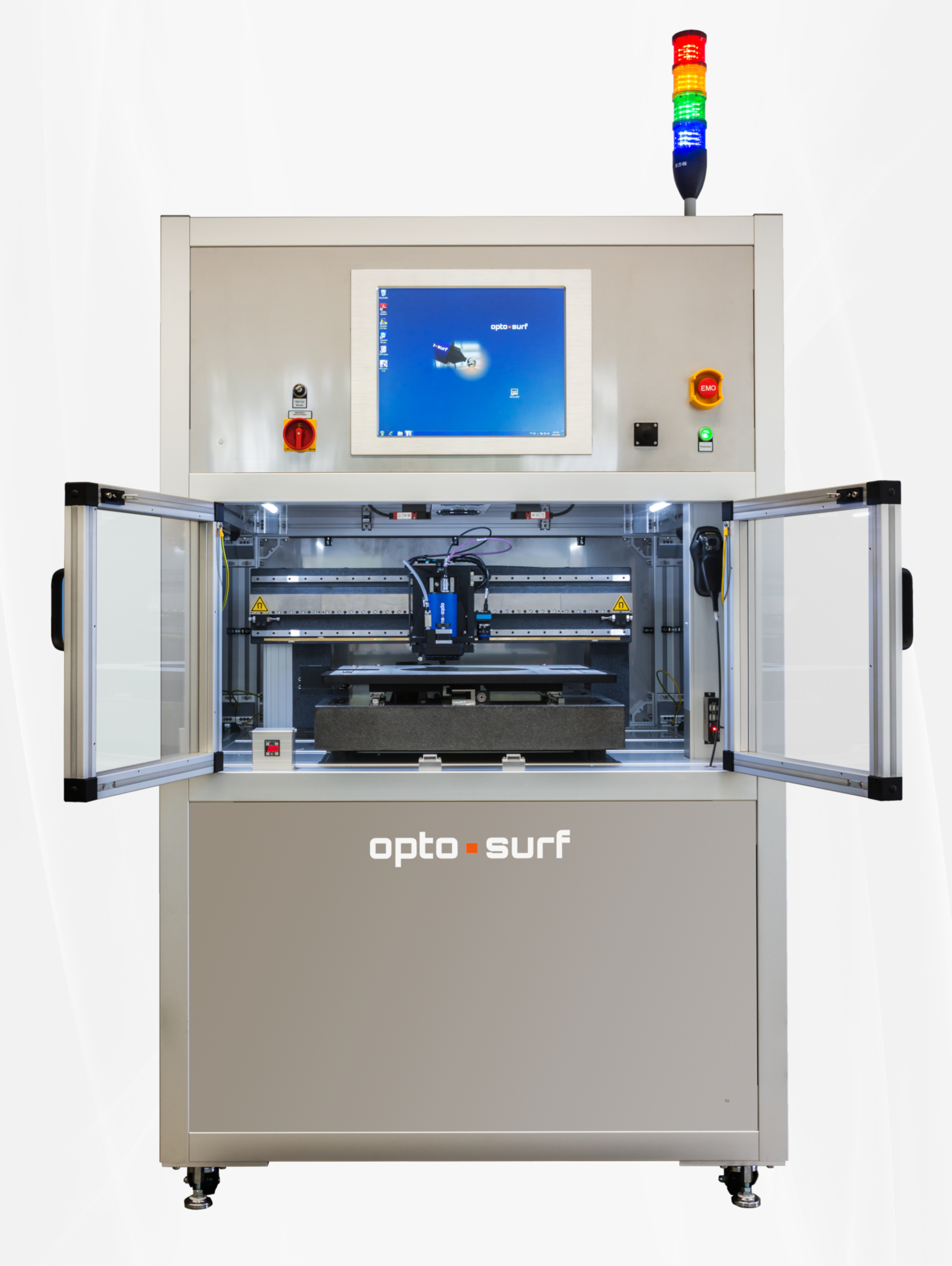

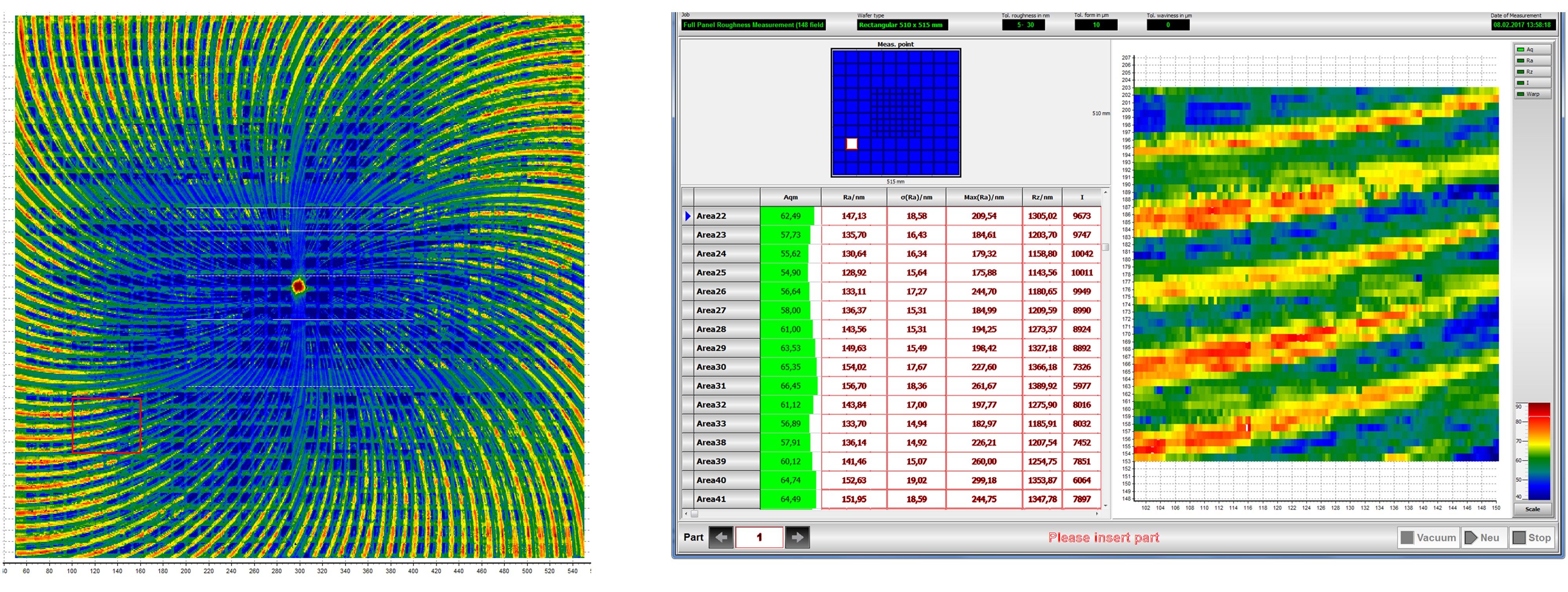

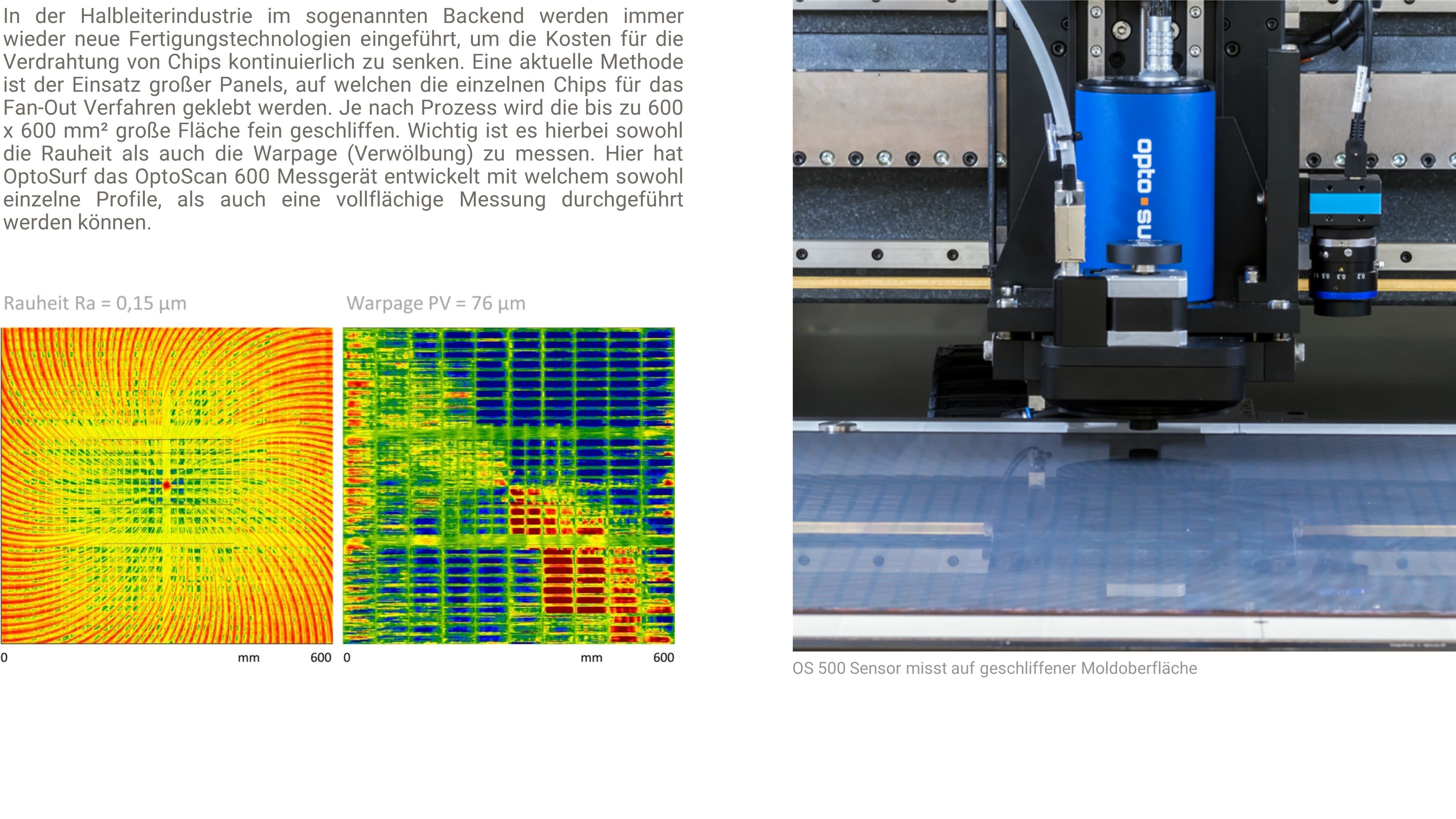

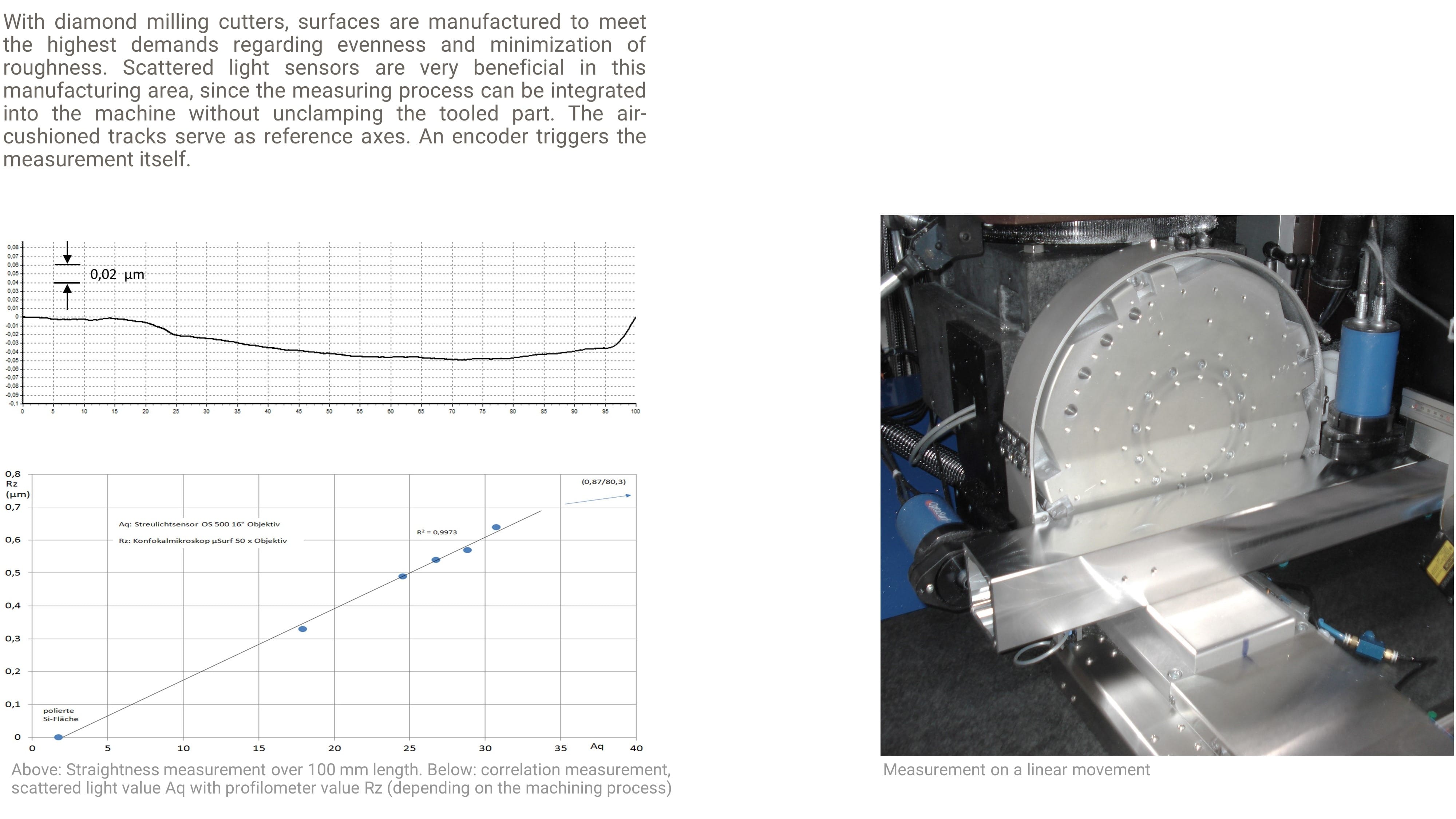

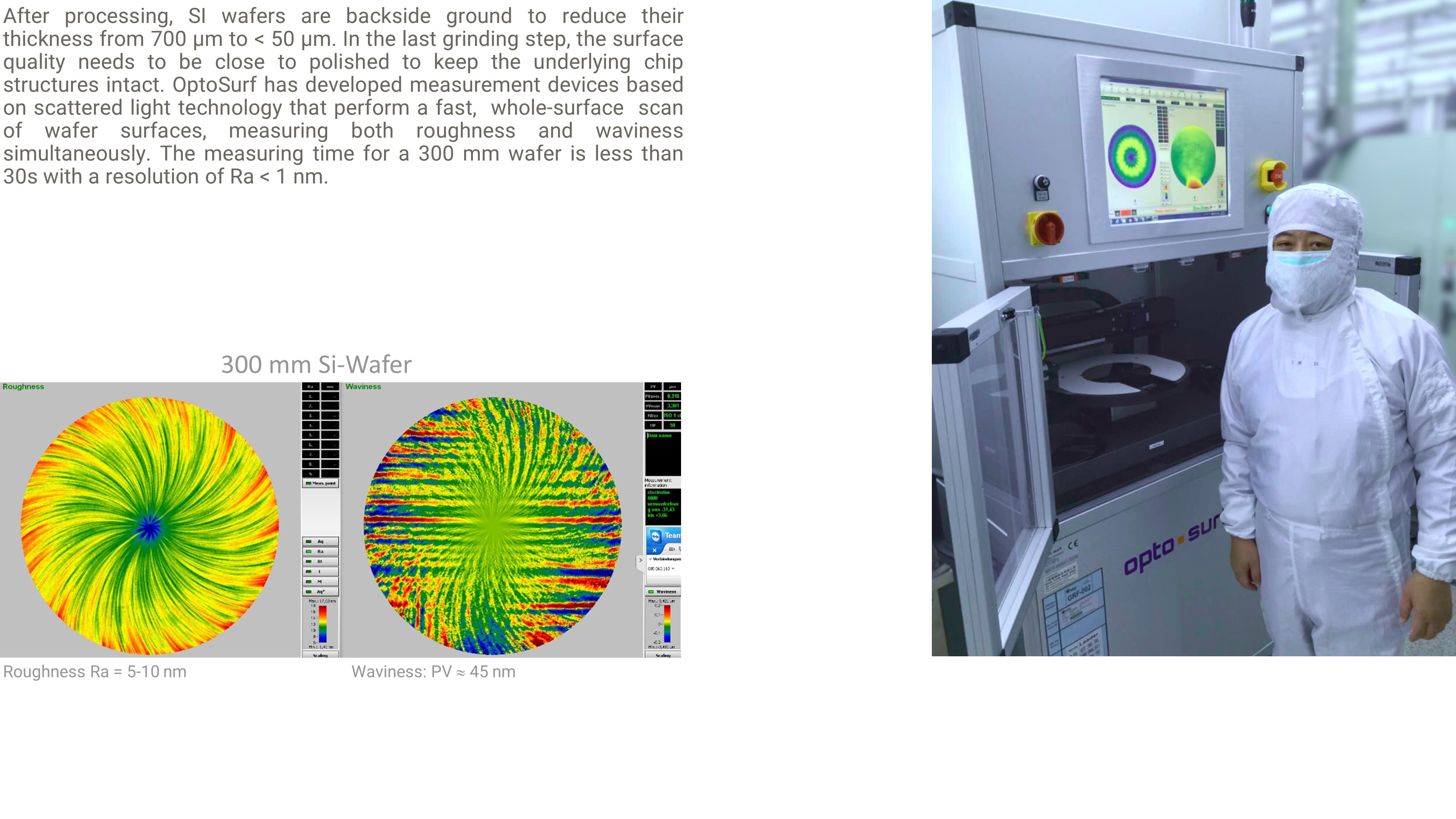

Panel measuring machine OptoScan 600

Whole surface roughness and waviness measurements on panels

OptoSurf developed the OptoScan 600 device especially to measure large semiconductor panels. Not only panels can be measured – the device can also be used for foils or flat parts like polished tools or mirrors.

The clean room capable OptoScan 600 can measure areas of maximum 600 x 600 mm². Different measurement programs are available: Line-scans in x- and y-orientation, partial and full scans, roughness analysis (Aq or – after creating a correlation – Ra, Rz), form and waviness. The system can be ordered with an additional vacuum chuck. Maximum feed rate is 600 mm/sec.