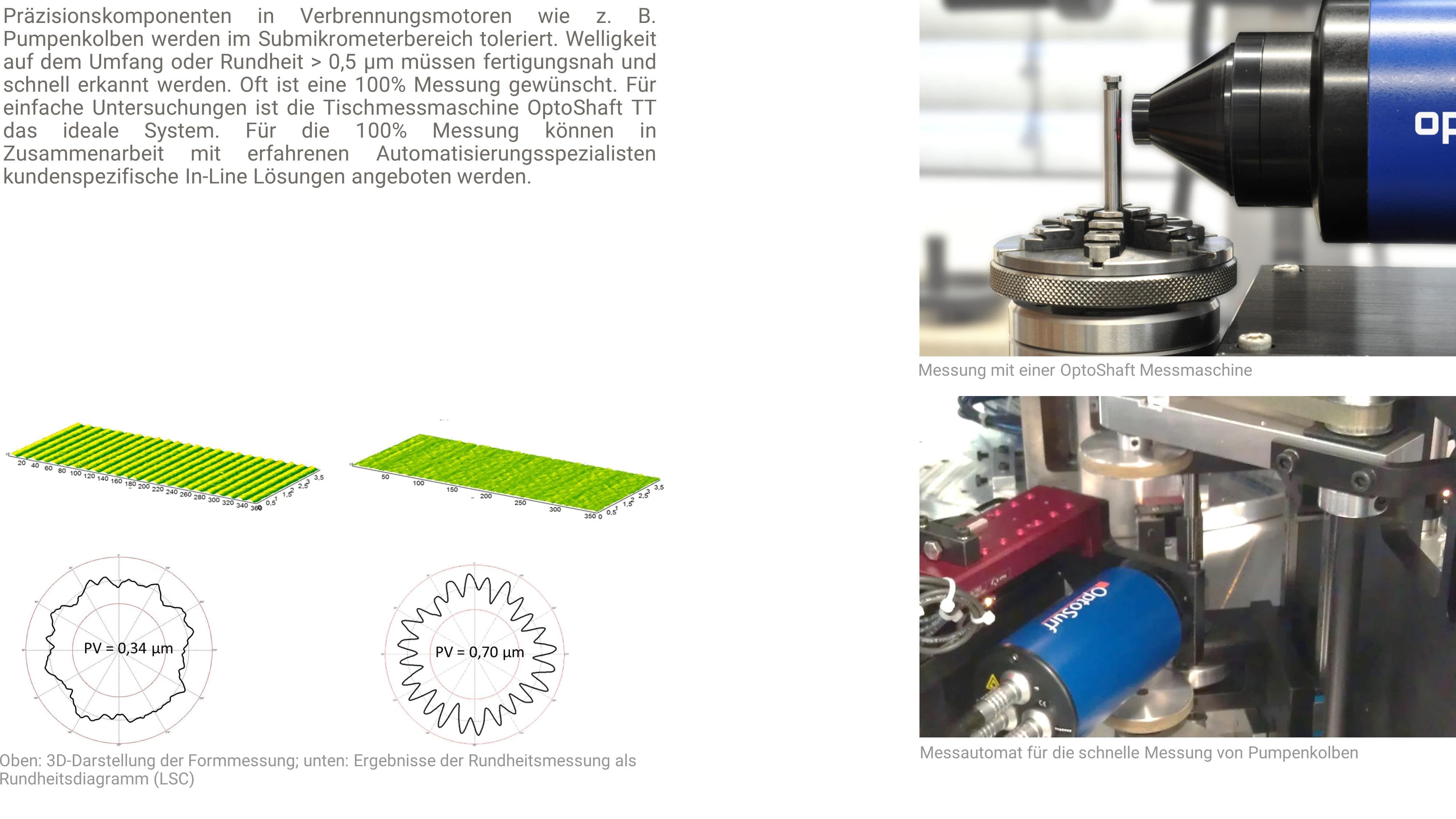

OptoGloss

Roughness and gloss measurements on coated surfaces

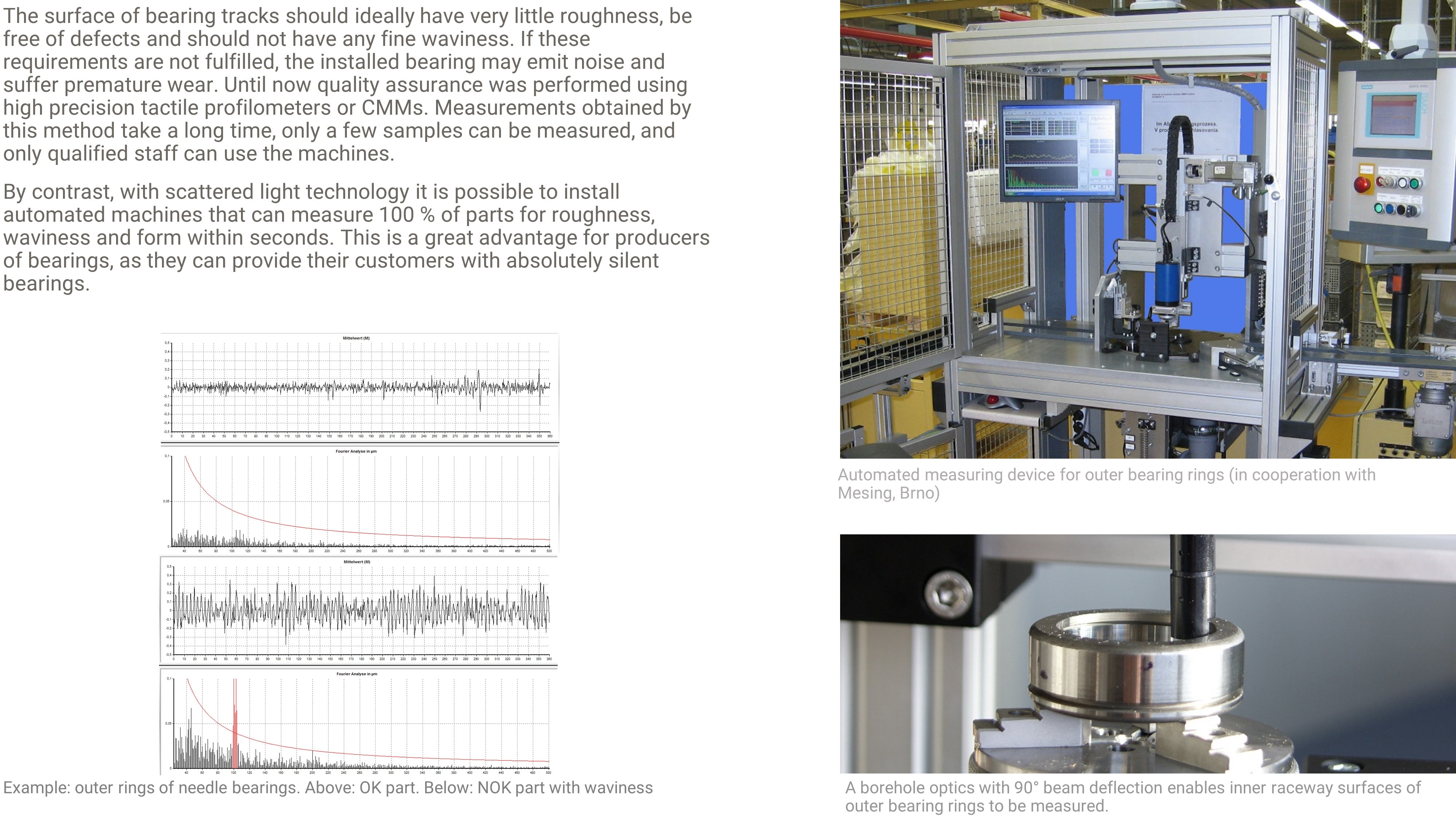

Coated productions parts often have to meet high standards regarding visual appearance. Differences in optical impressions between batches are not uncommon. In contrast to conventional gloss or roughness testers, scattered light technology is able to detect these differences.

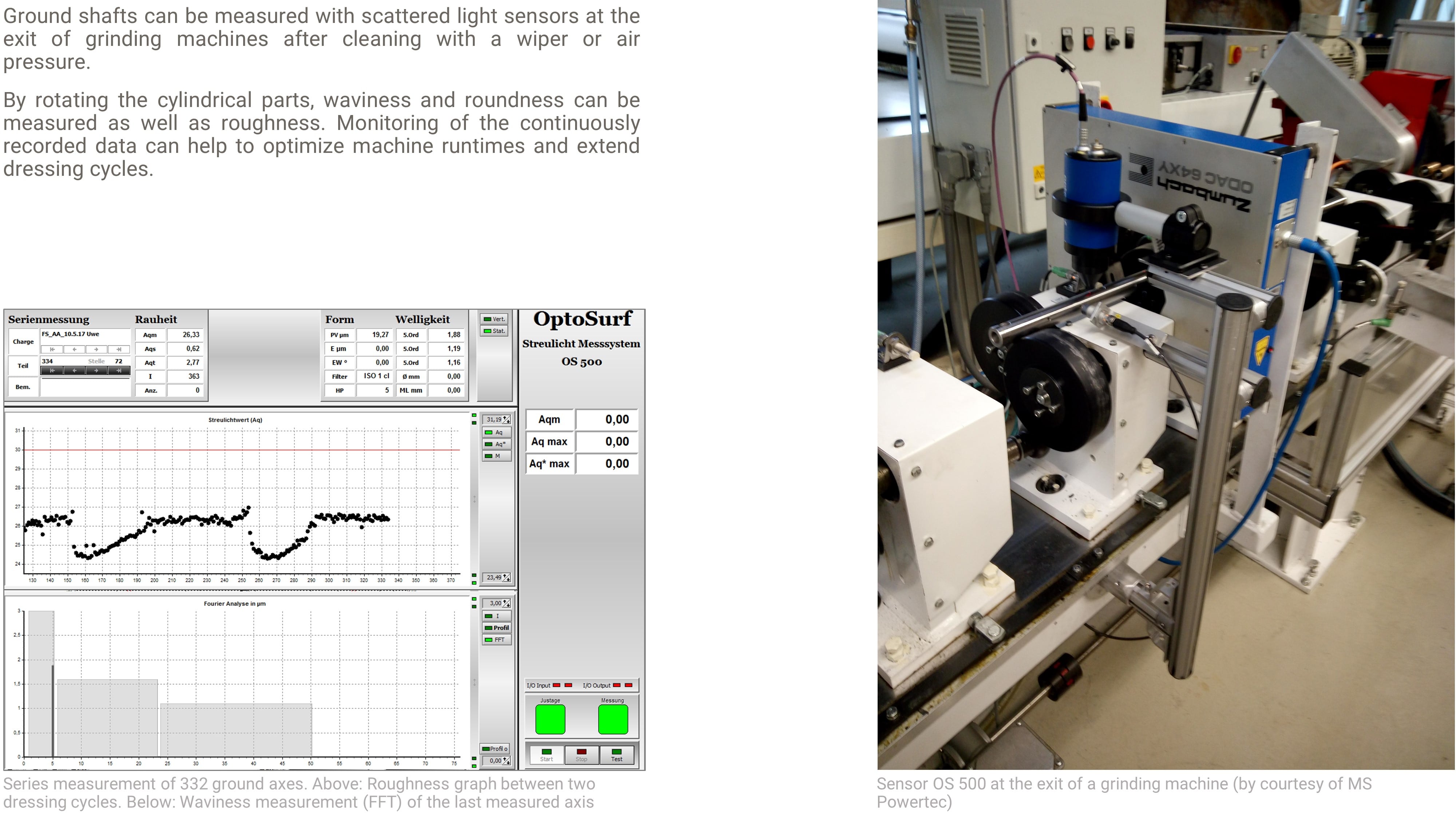

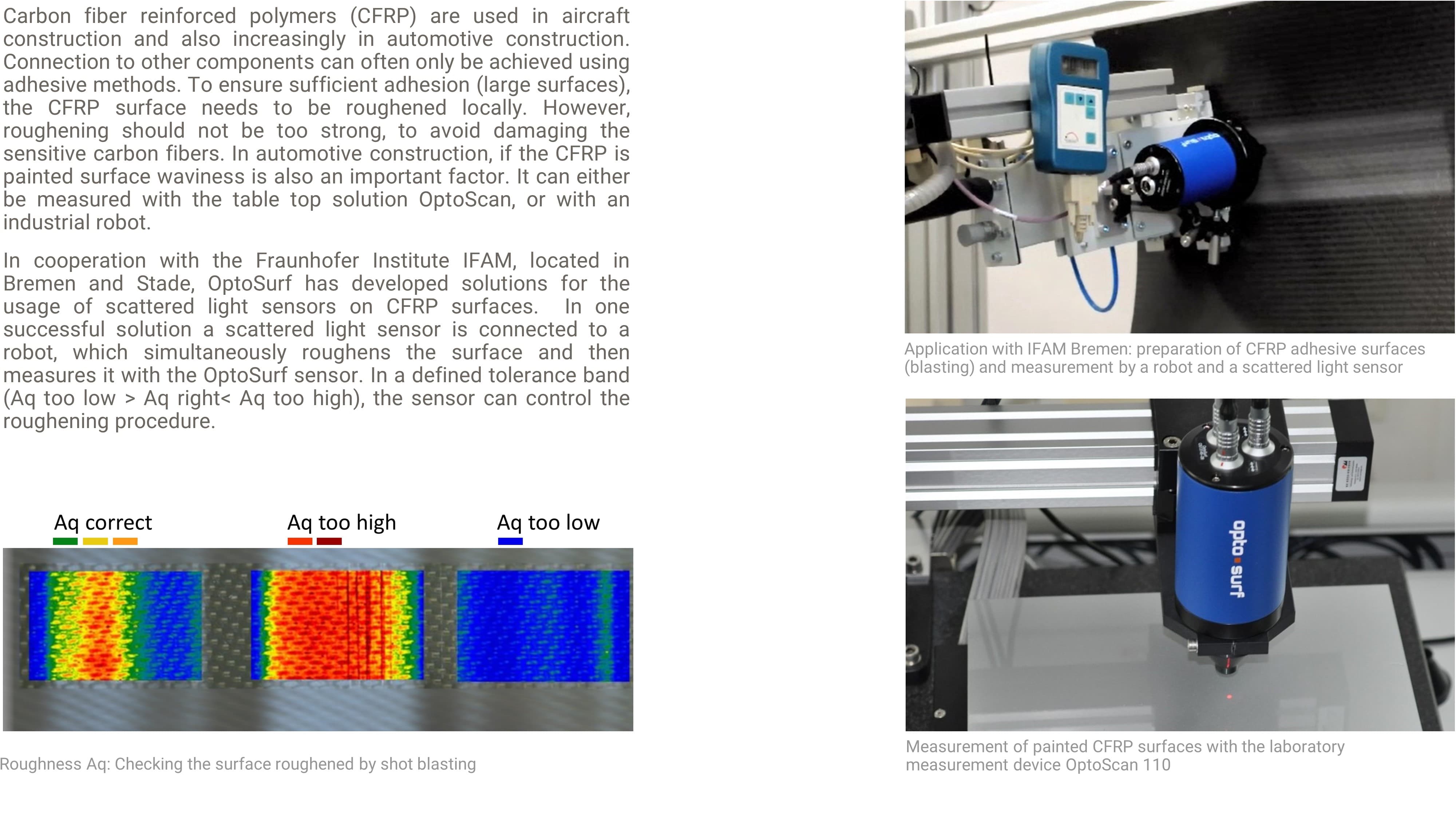

The OptoGloss measurement system is a manual device for measuring surface roughness or gloss of coated surfaces, based on scattered light. Smaller parts from all areas like automotive, bathroom fitments, multimedia or medical engineering are typically measured. Thanks to the contactless measurement principle, probes will not be scratched during measuring, which is a huge advantage compared to other measuring techniques. The system is suitable for measuring tasks in quality assurance immediately after coating, or for the receiving inspection by customers.

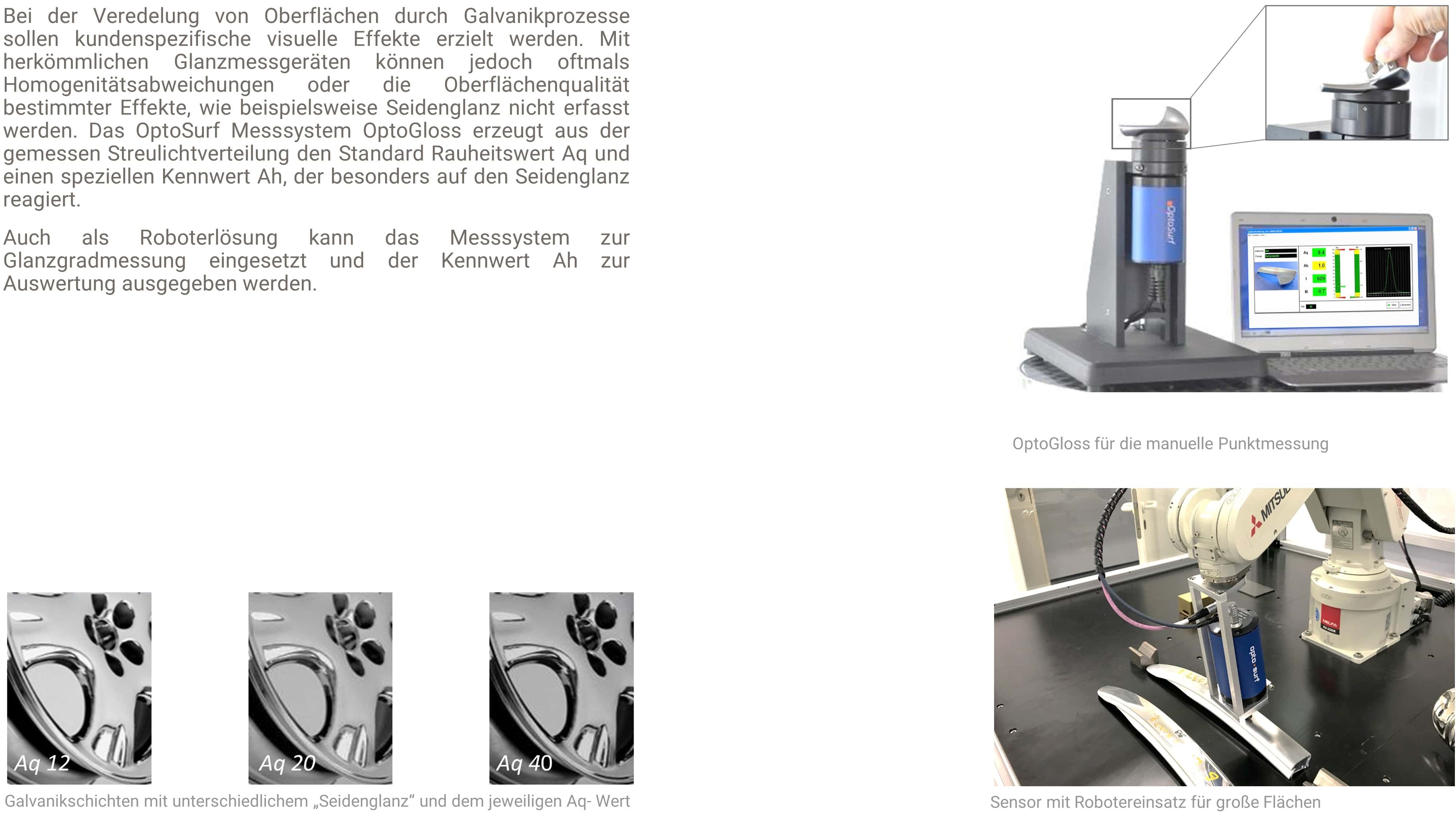

In case larger objects are to be measured, OptoSurf offers a Robot-based solution.