Ball stud measuremant device BS

Automatic measurement device for ball studs

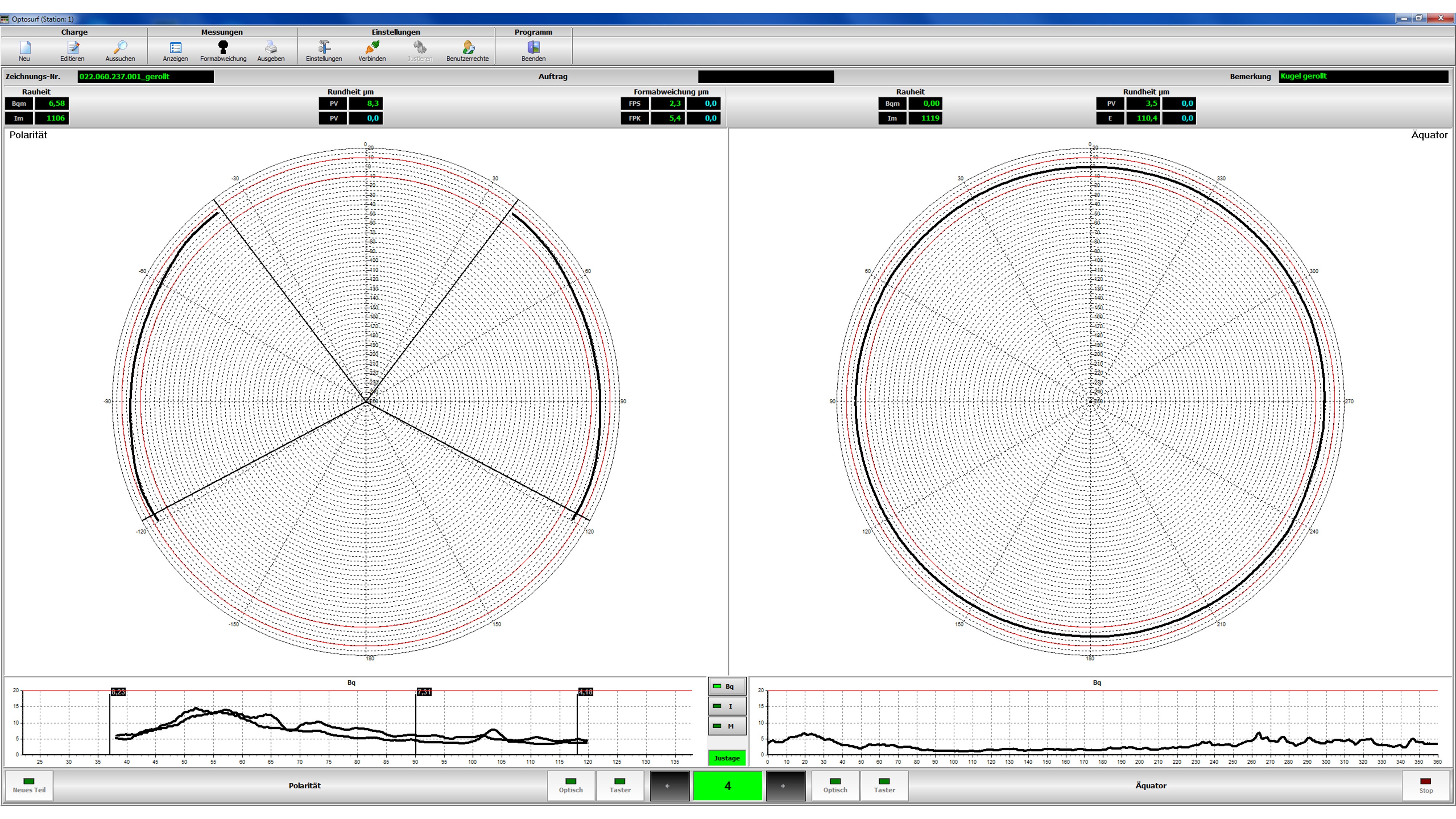

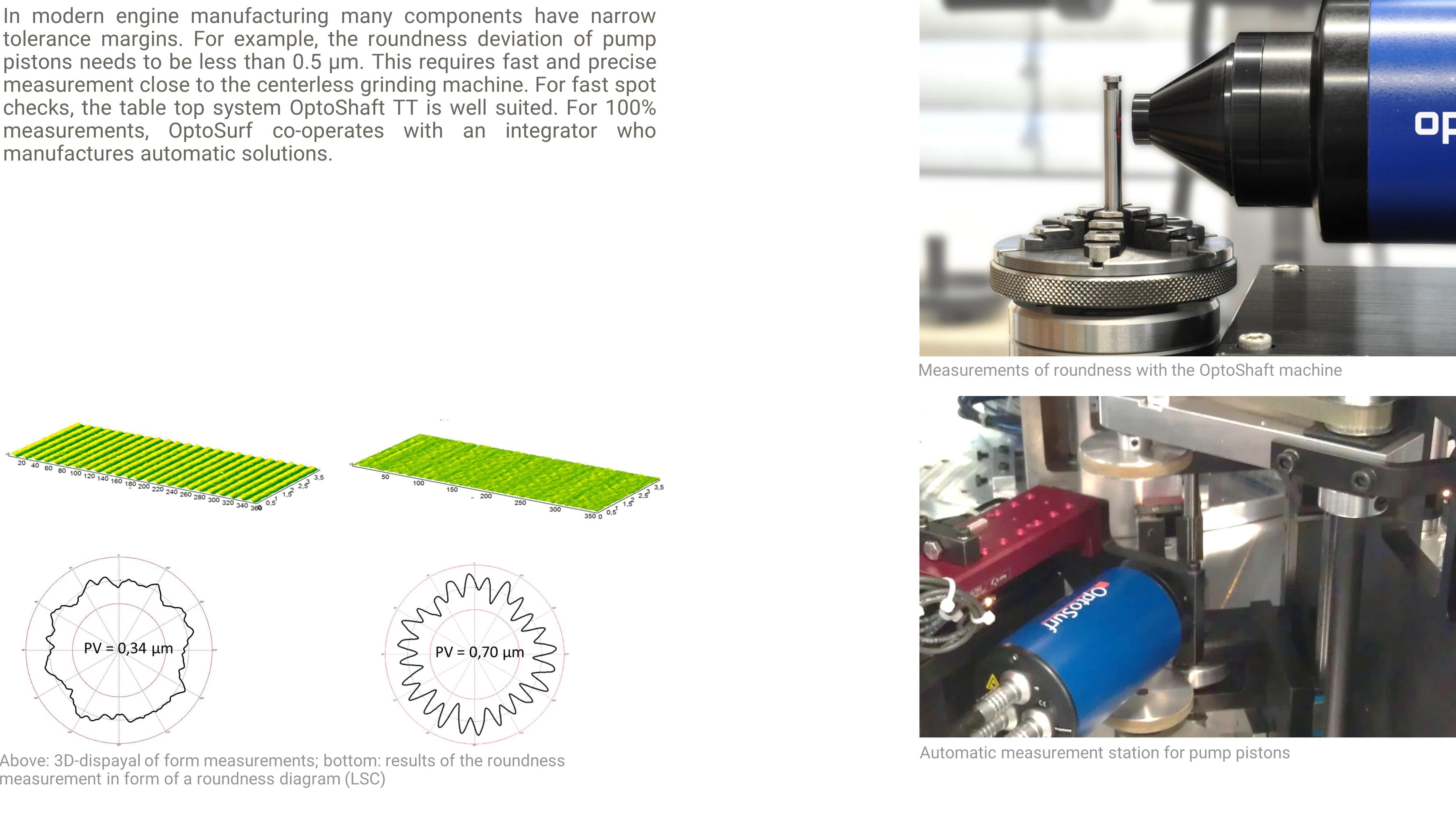

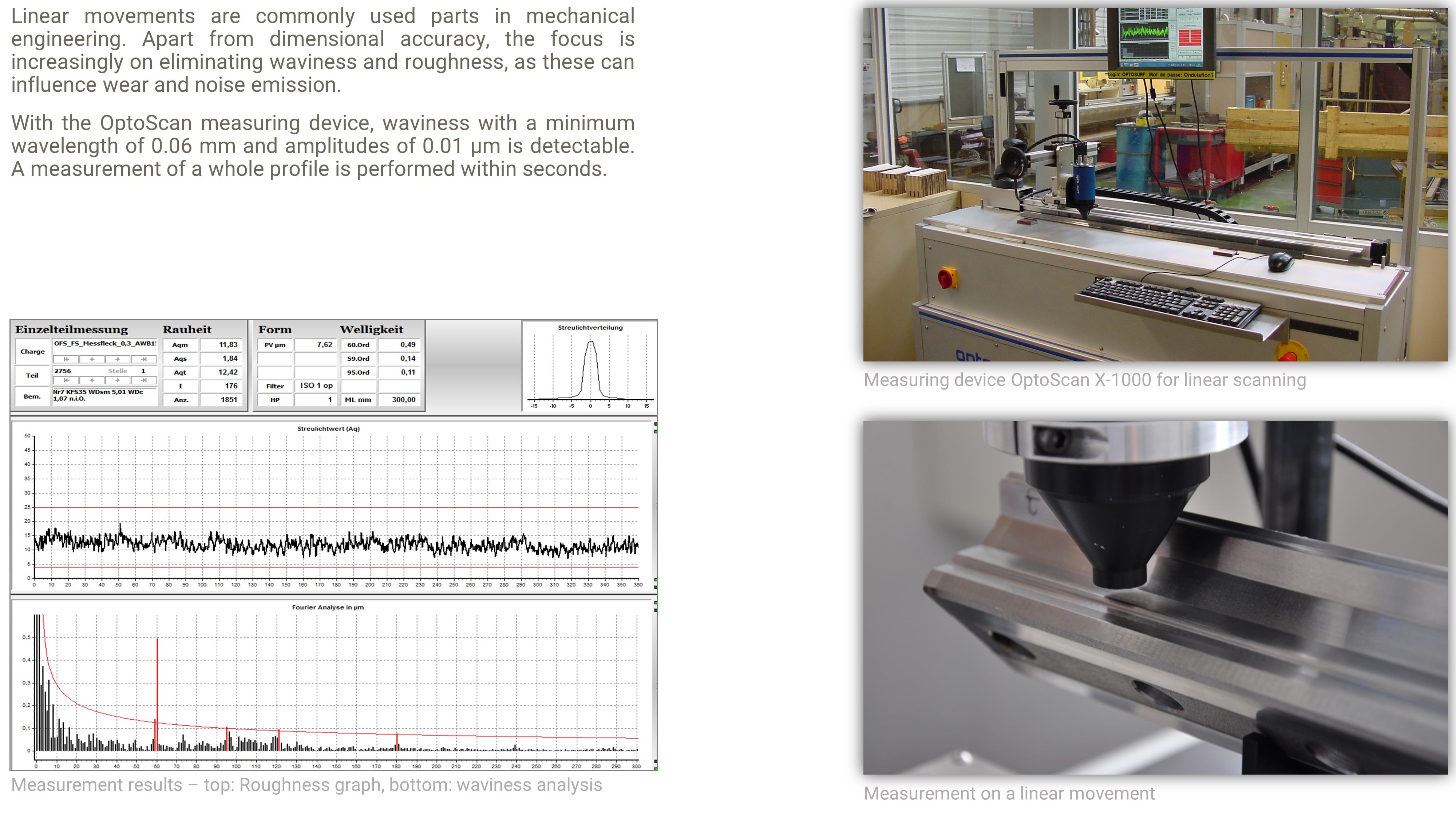

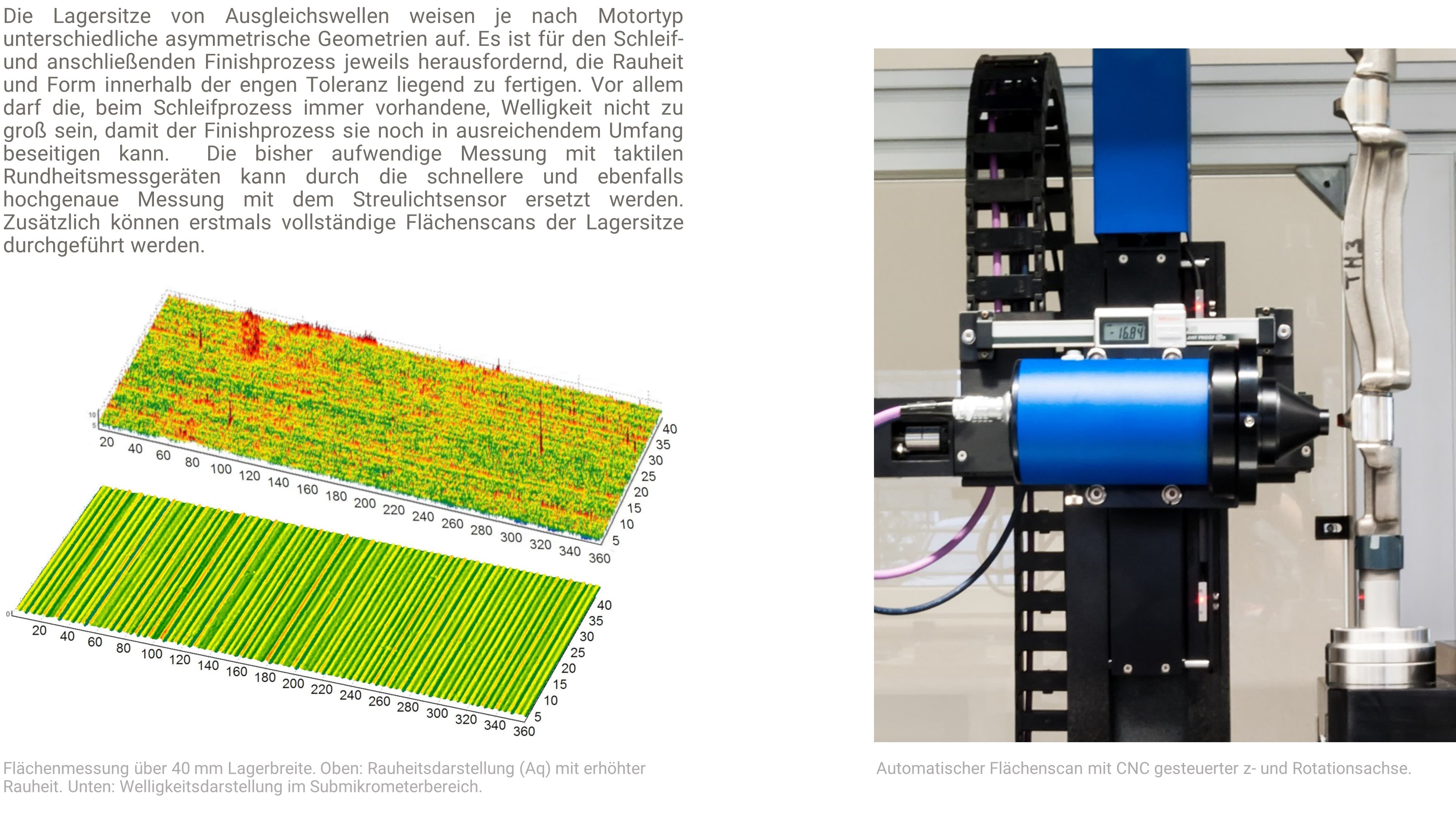

A commonly used component in chassis technology is the ball stud, which is attached in bearing cups. For developers and customers, smooth movements without stick-slip effects are aimed for. Responsible for stick-slip effects, amongst others factors, are the microstructure and geometrical form of the ball. OptoSurf offers producers of ball studs a production-oriented solution for simultaneously measuring roughness and form deviation. An especially important value is Bq (VDA 2009), which correlates to breakaway torque and is only measurable with OptoSurf scattered light sensors.

After positioning the pin in a three-point support, the measurement is performed automatically. To measure turned pins, a mechanical stylus can be integrated and swiveled in as required. Measurements with scattered light take less than a second. The machine can measure form deviations in the range of < 0.5 µm.