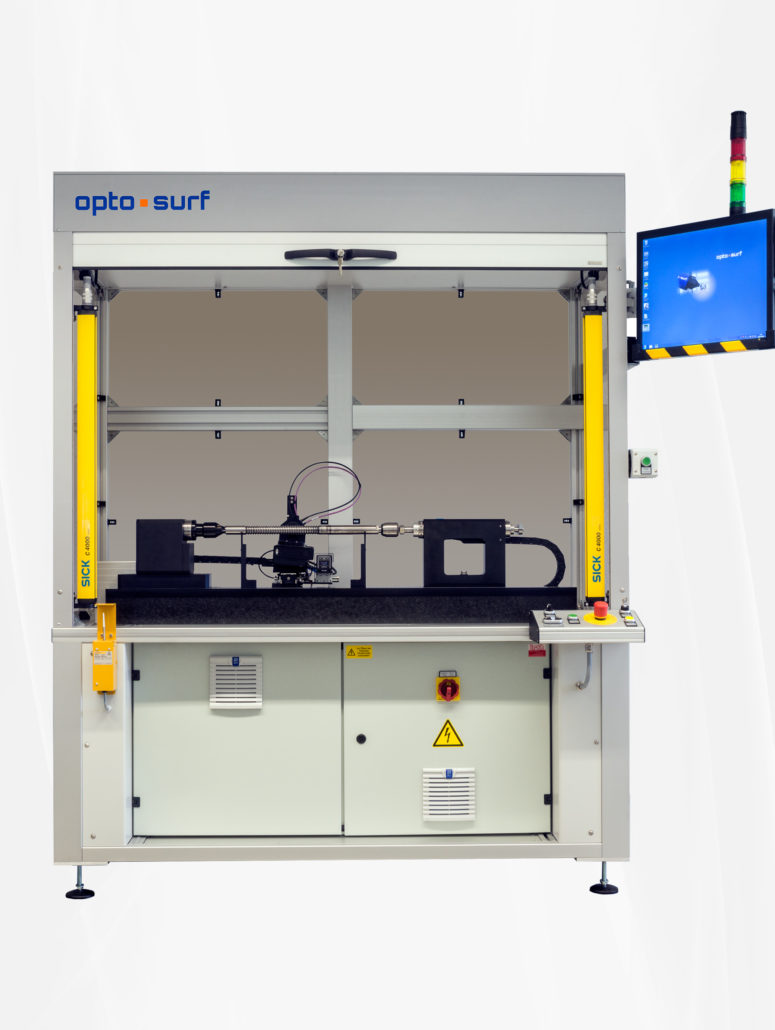

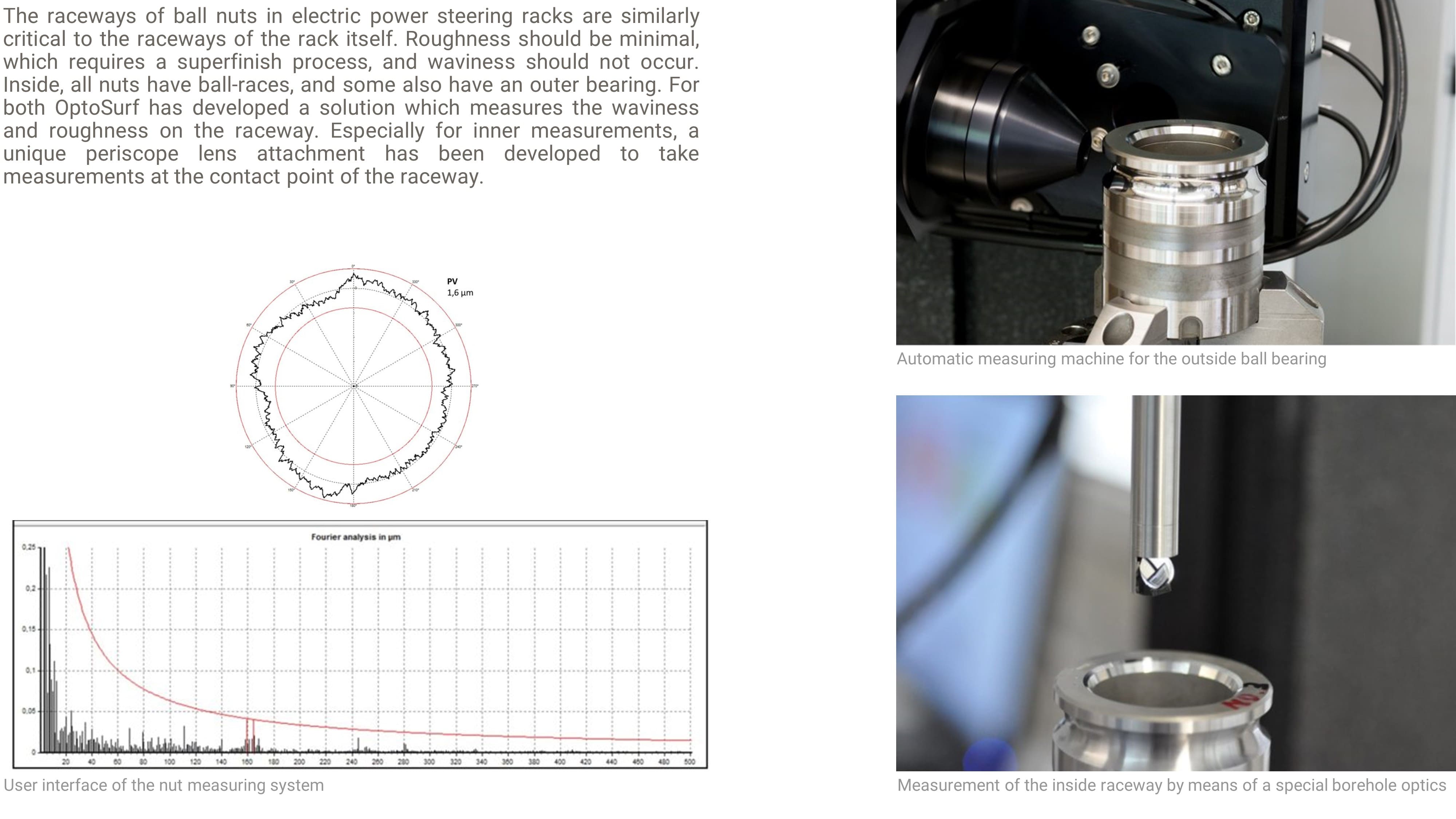

OptoRack

Steering rack and spindle measurement device

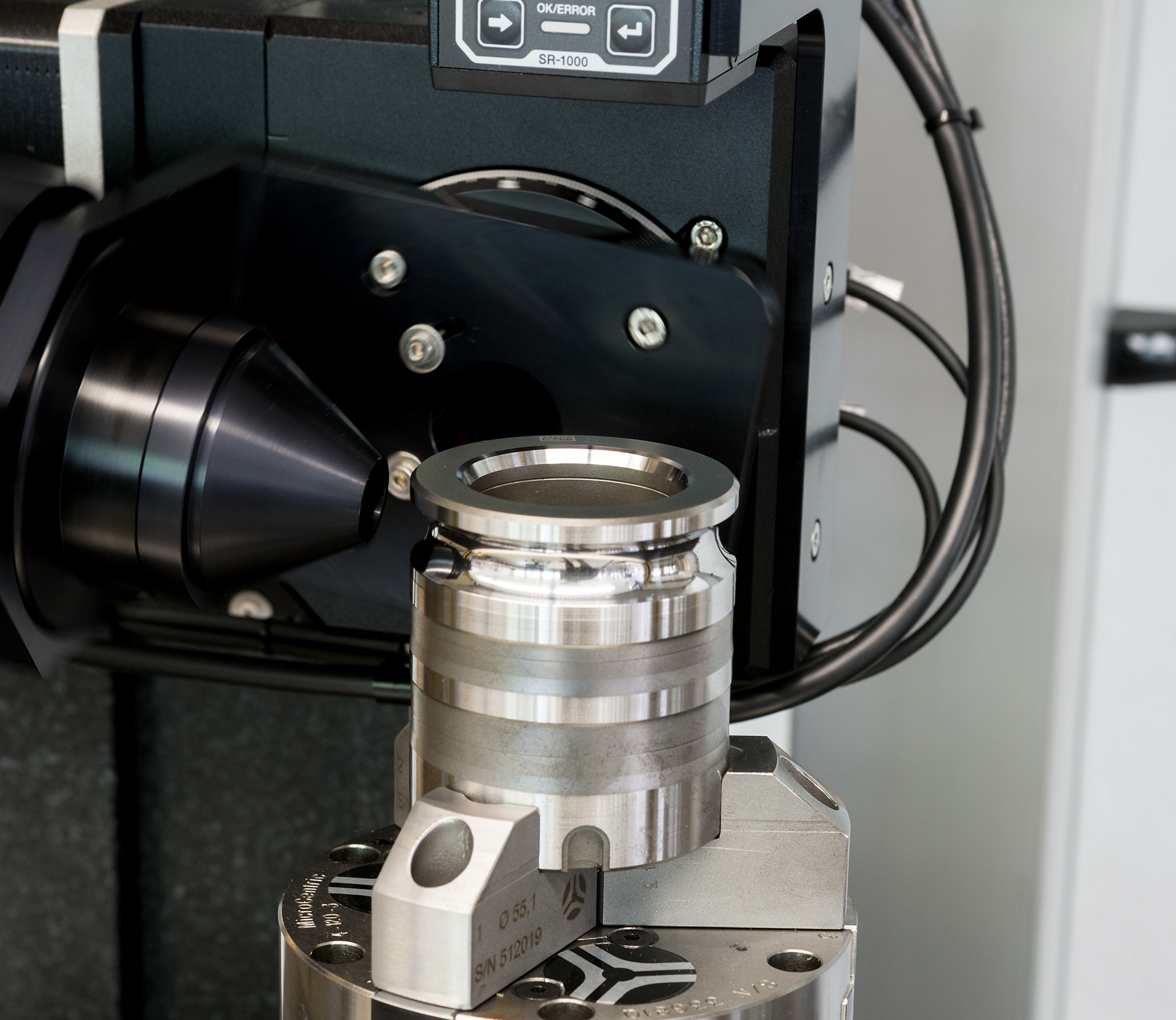

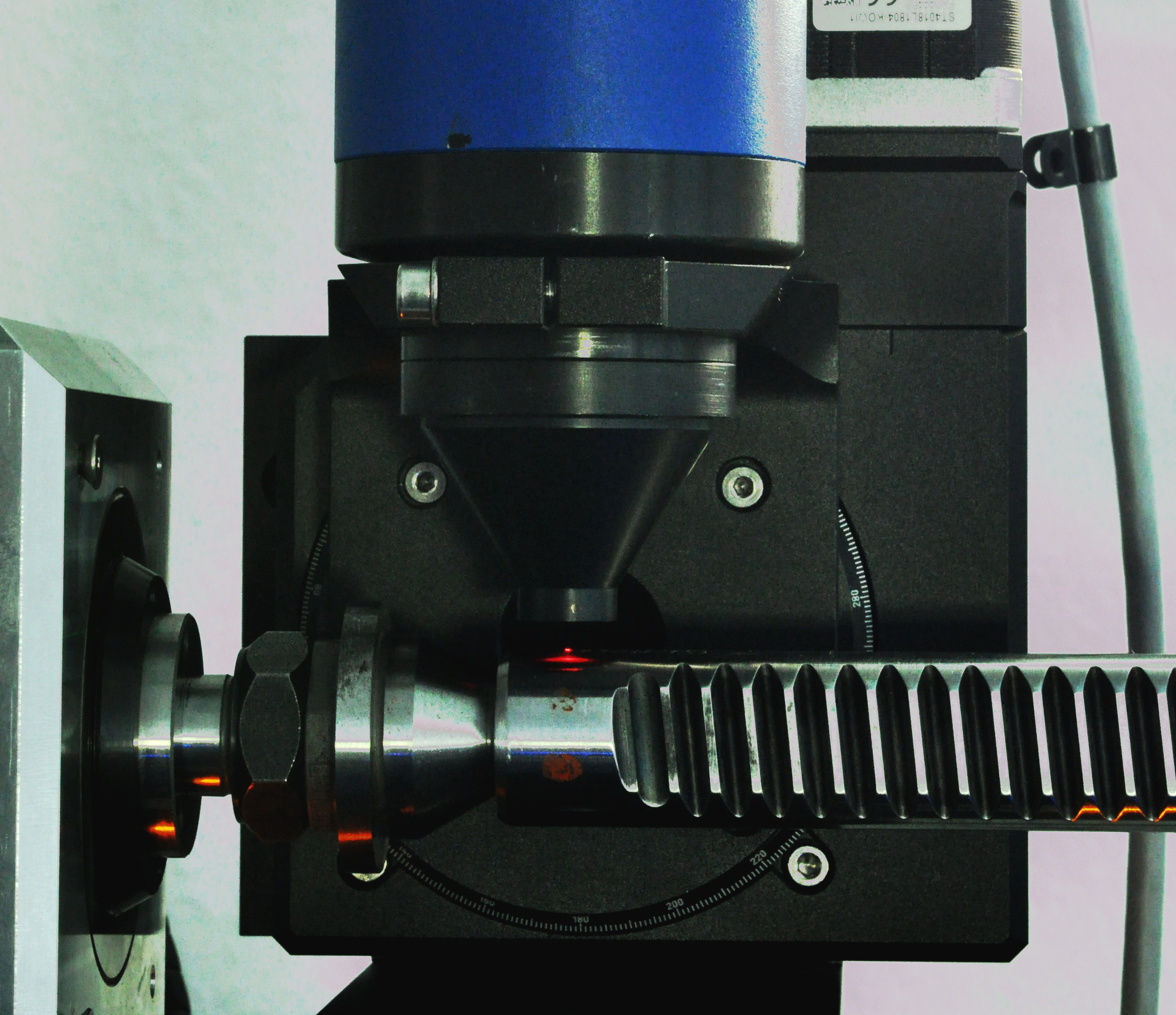

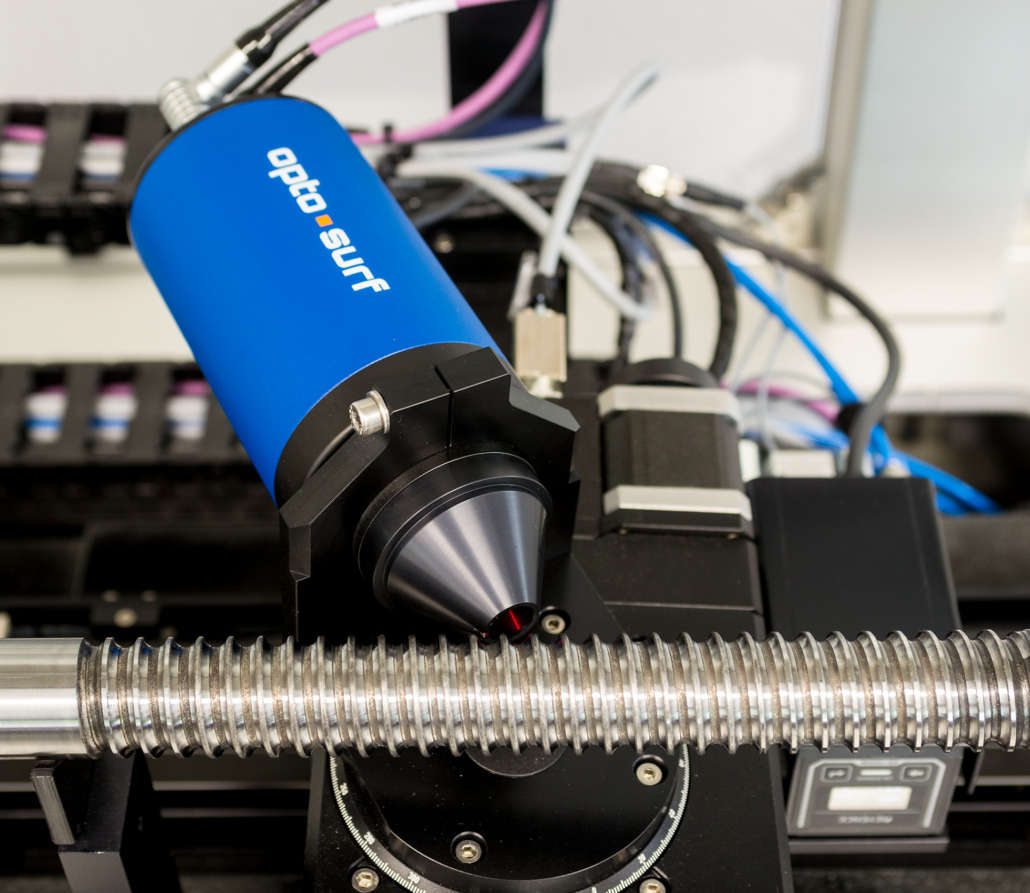

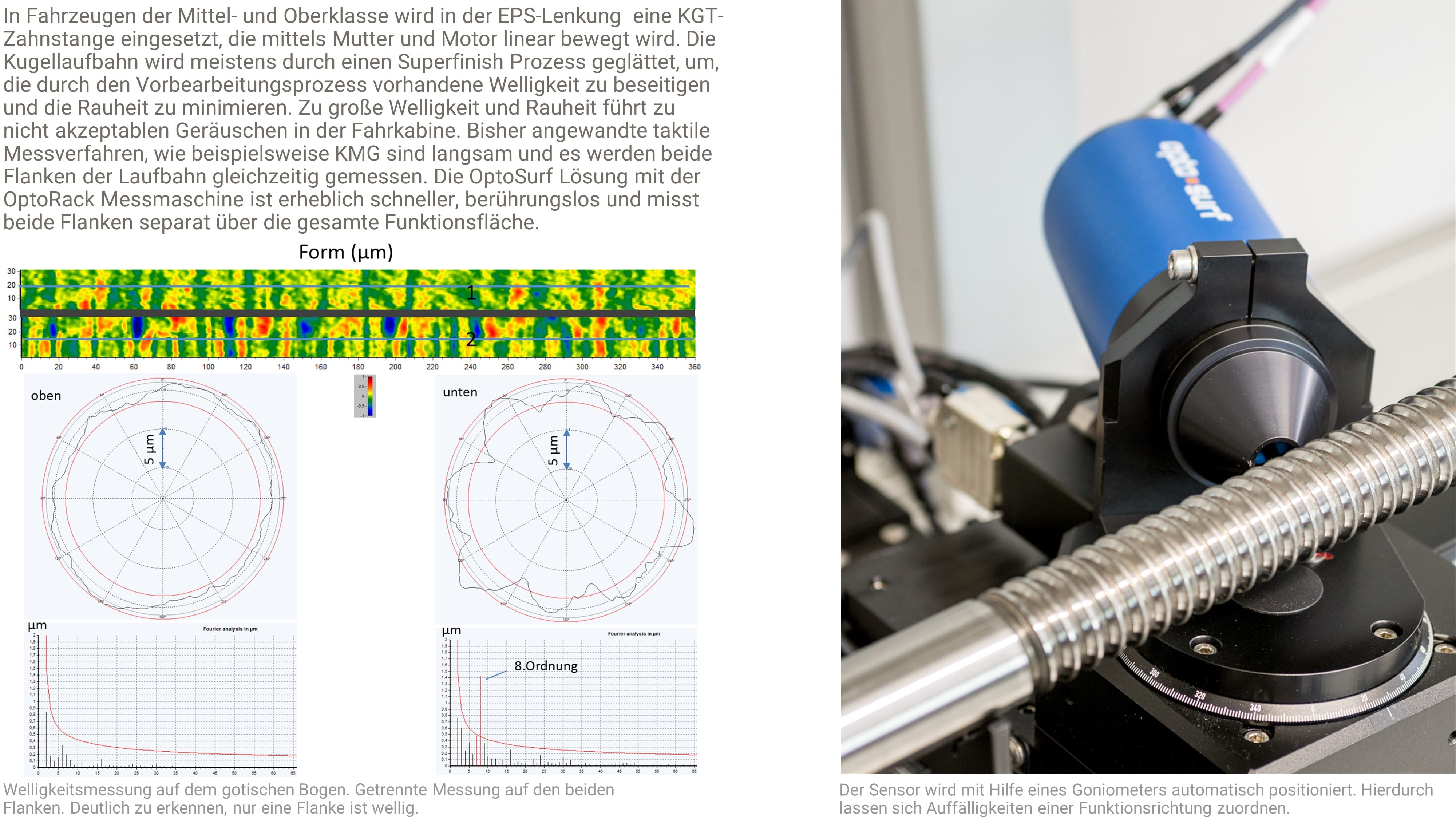

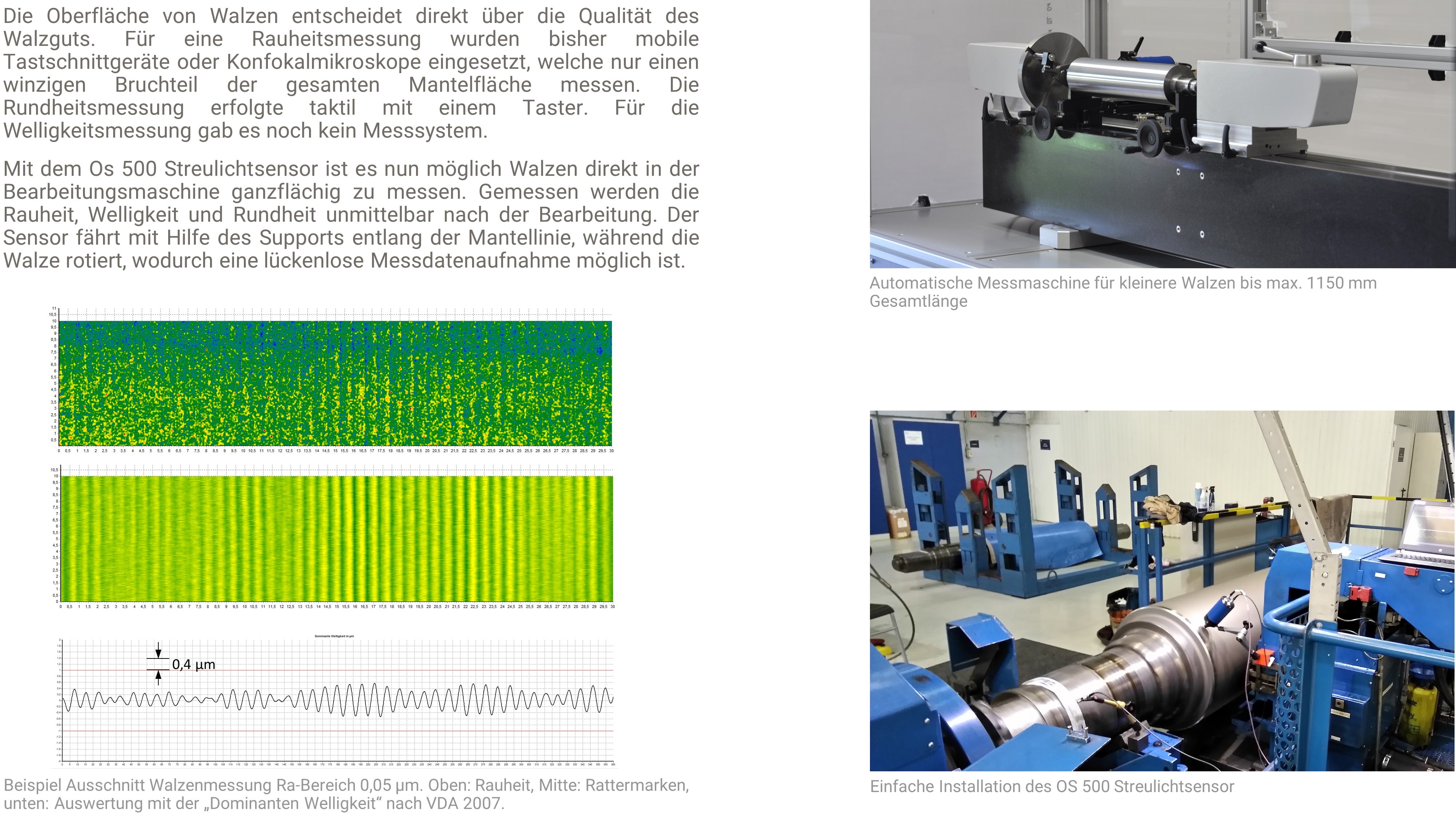

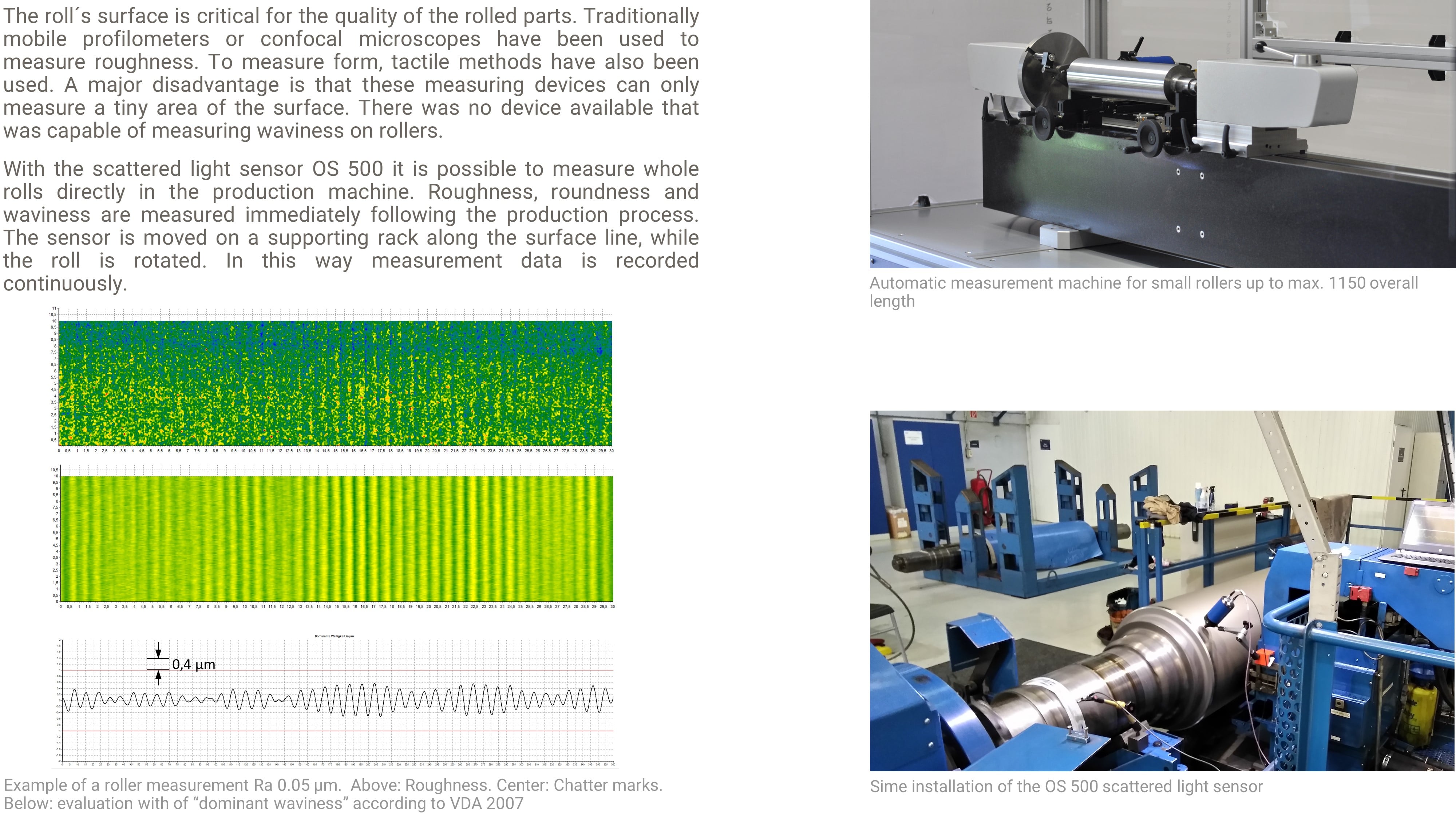

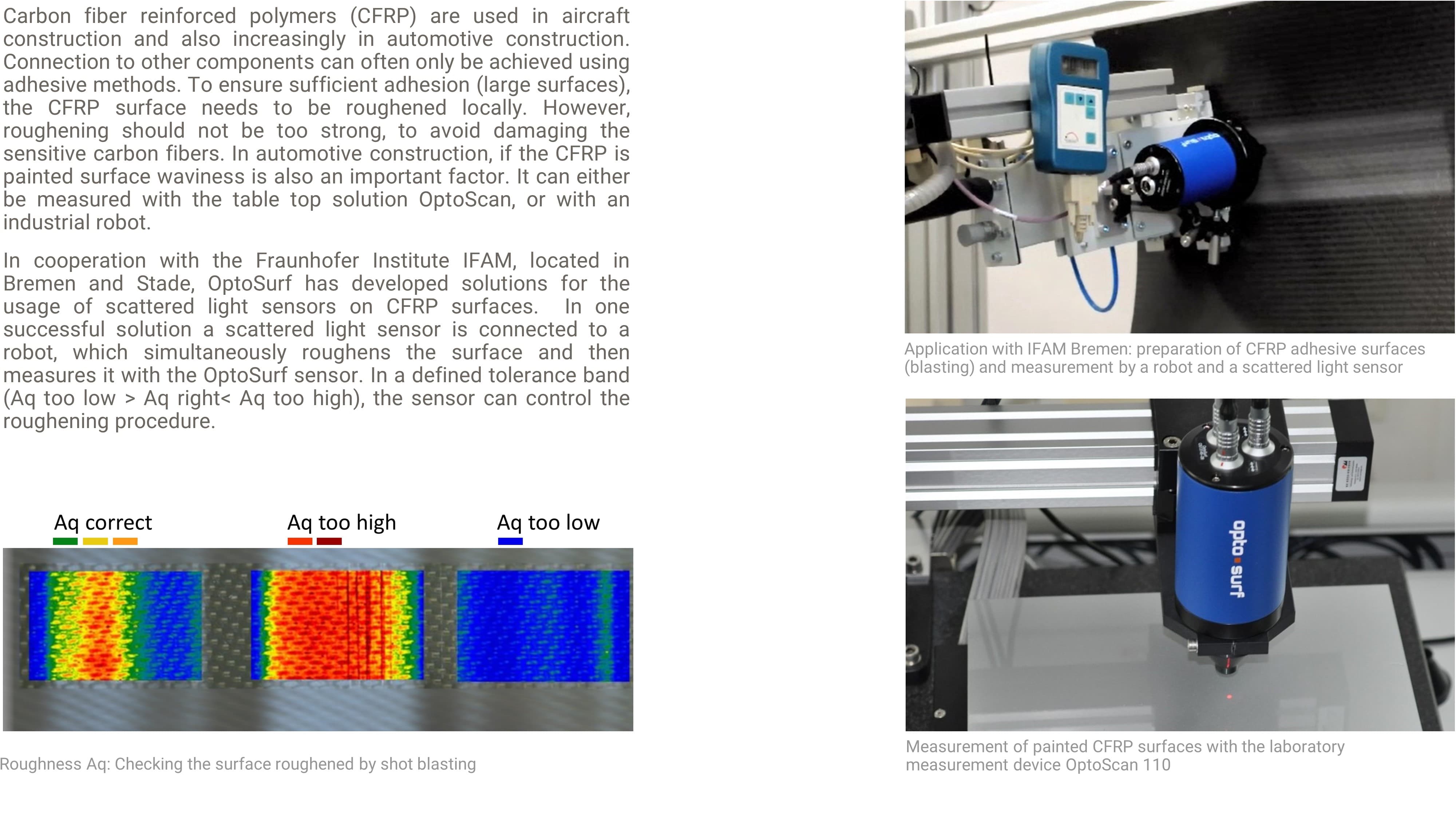

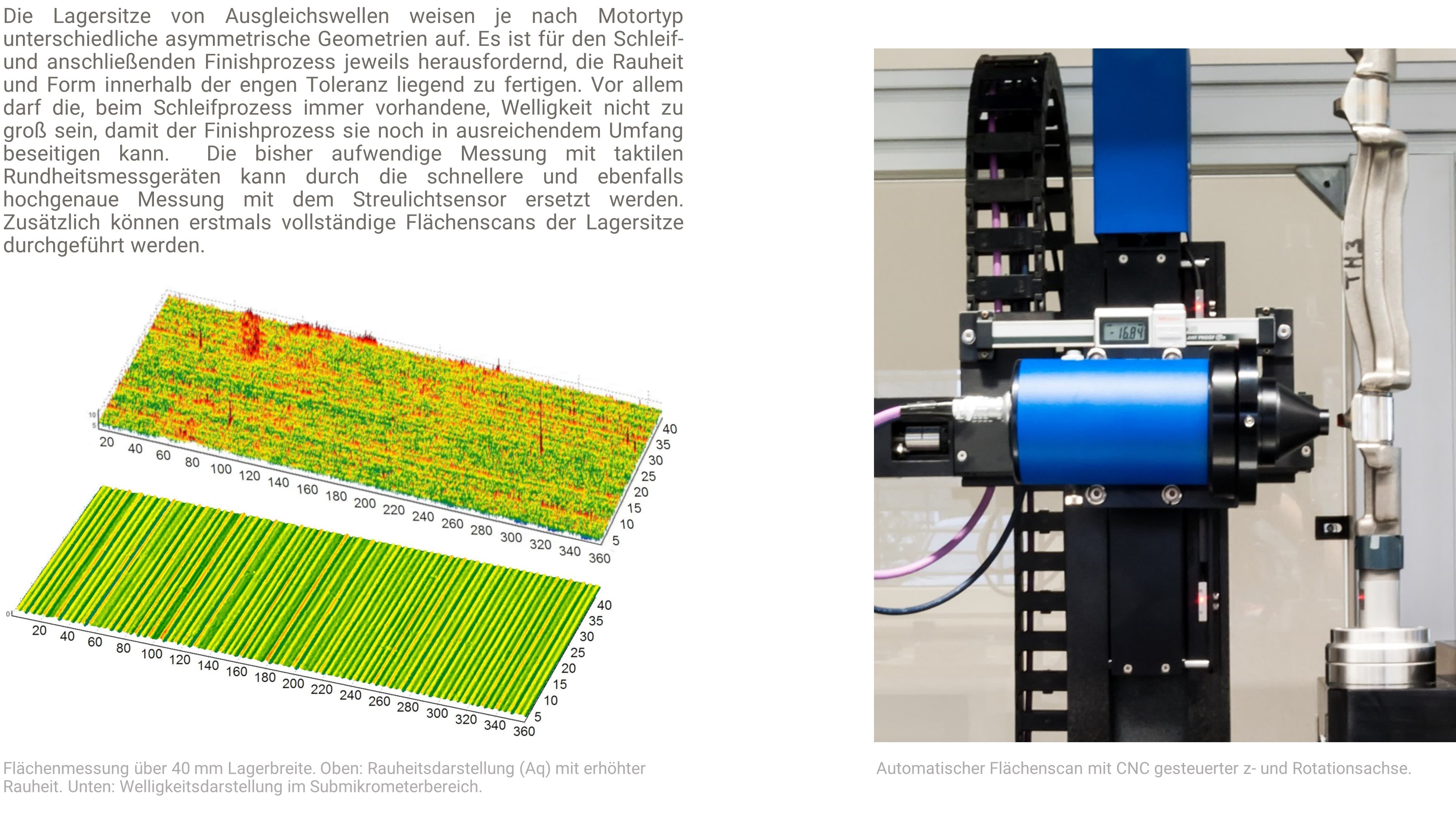

Ball screws are used to translate a rotary movement into a linear movement. The parts are used in tooling machines as well as in steering systems to translate the rotary movement of the electric motor which drives a pinion shaft in a linear direction. Especially in steering systems, functional behavior and possible noise emissions depend on the surface finish of running surfaces. Intelligent technical grinding and finishing processes help to minimize roughness and waviness that lead to potential wear and noise emissions. OptoRack measuring devices are ideally suitable for the process control and quality assurance of steering racks, ball screws and ball screw nuts.

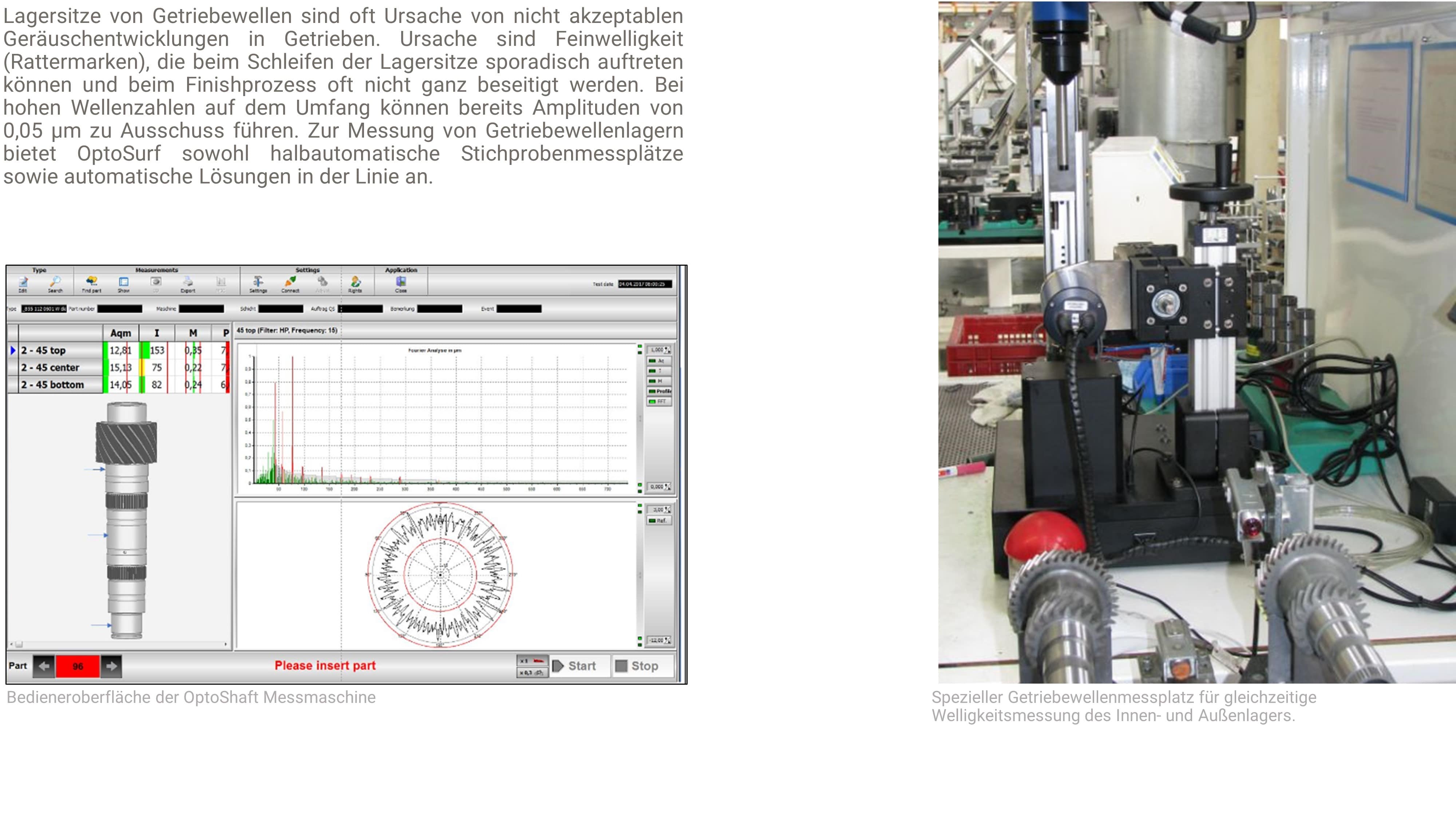

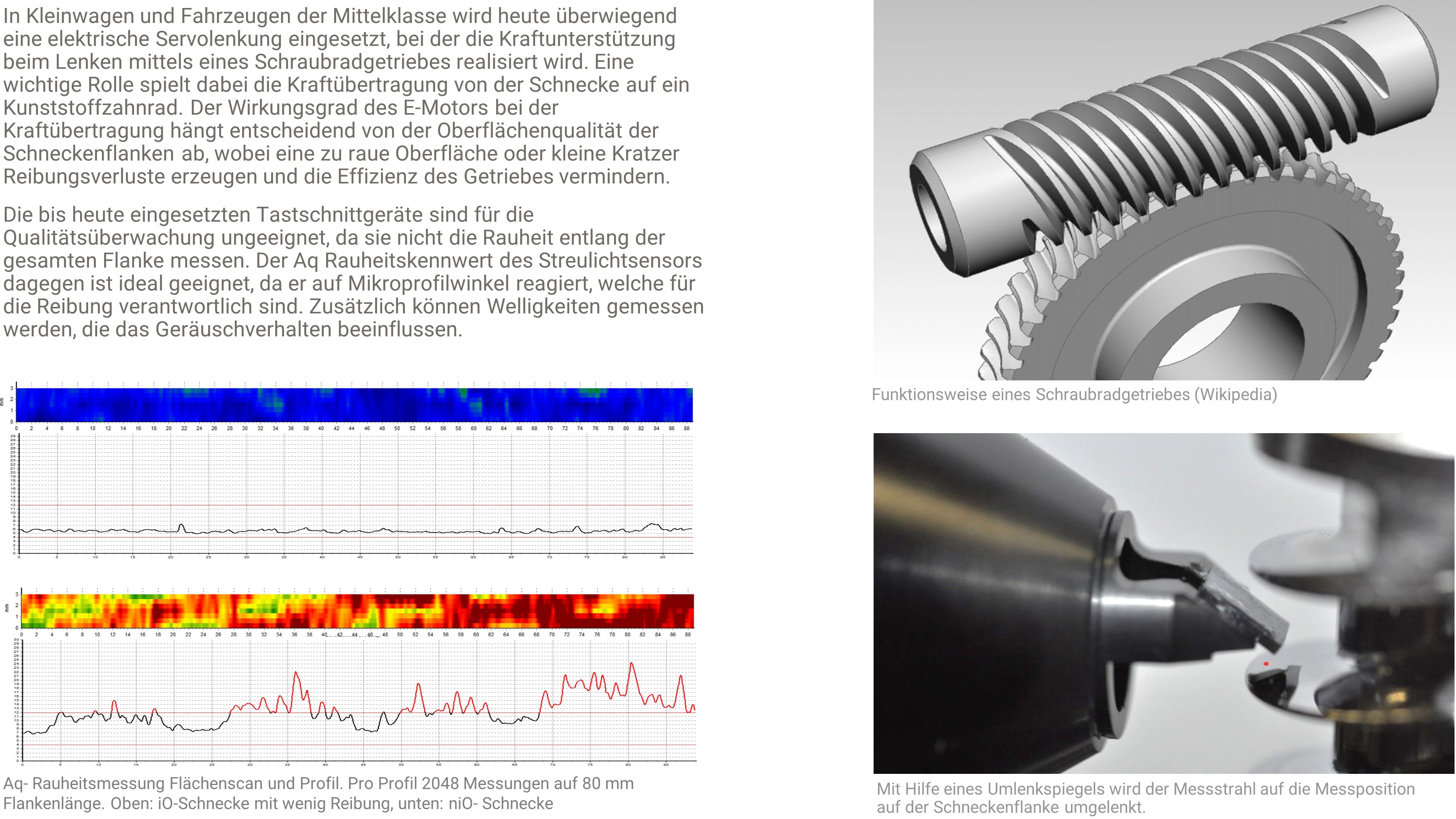

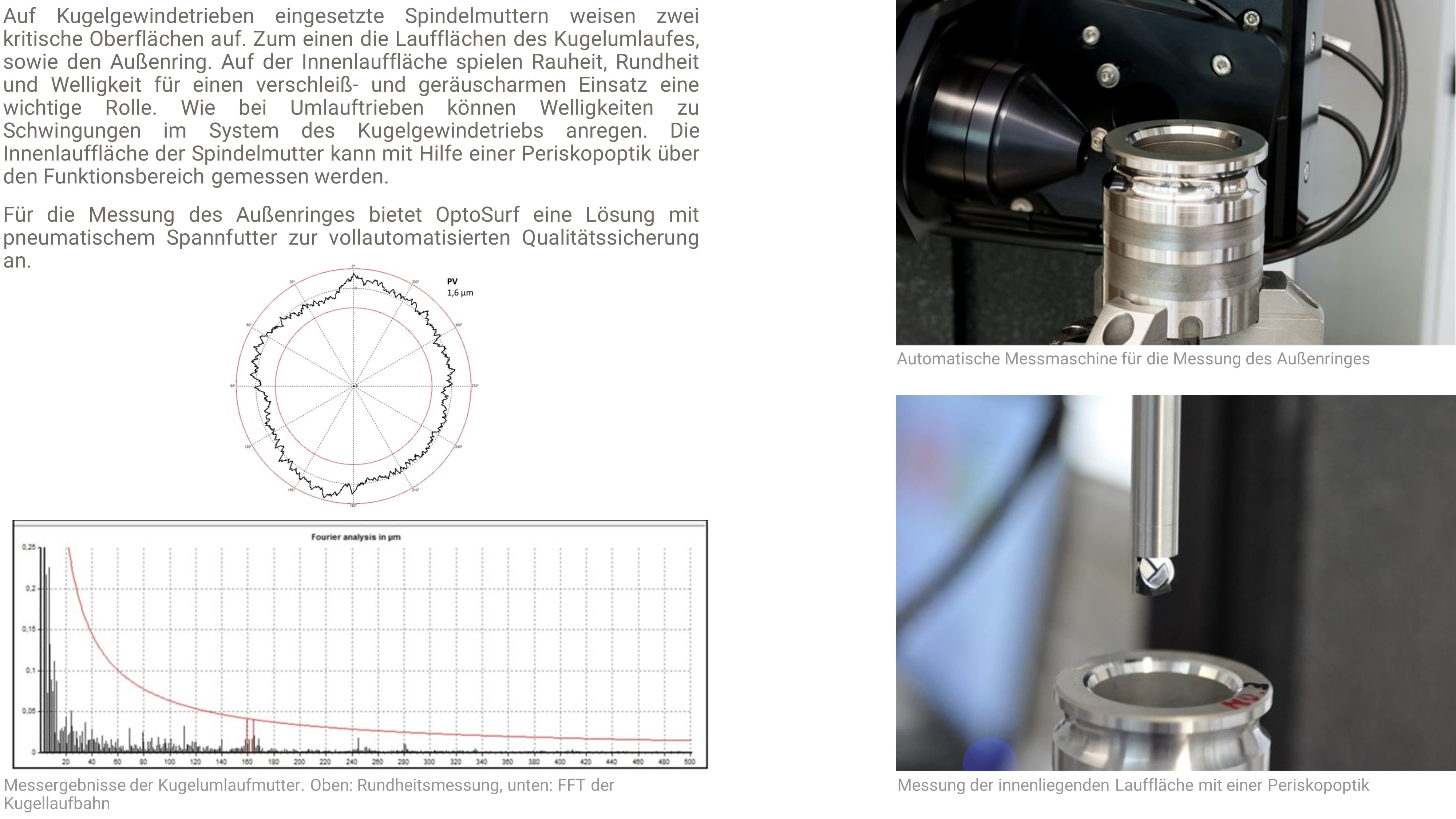

Fitted with a CNC-controller, the OptoRack spindle measurement device measures the whole running surface while rotating the spindle. A goniometer positions the sensor perpendicular to both tracks separately. After positioning the spindle, the measurement will start automatically. Both roughness and waviness are recorded.