OptoBot

Robot based measurements

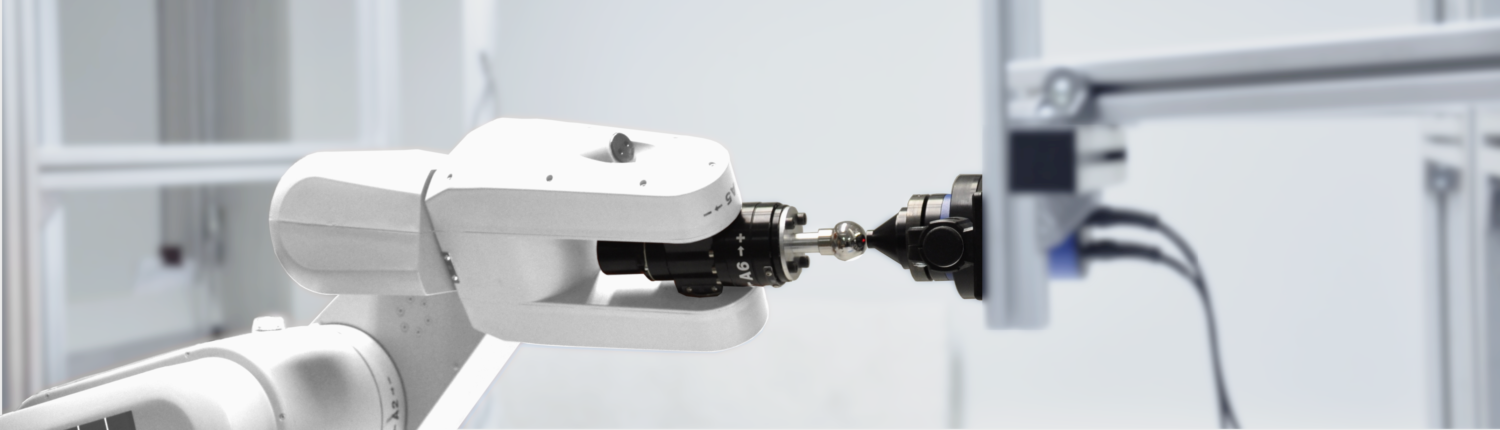

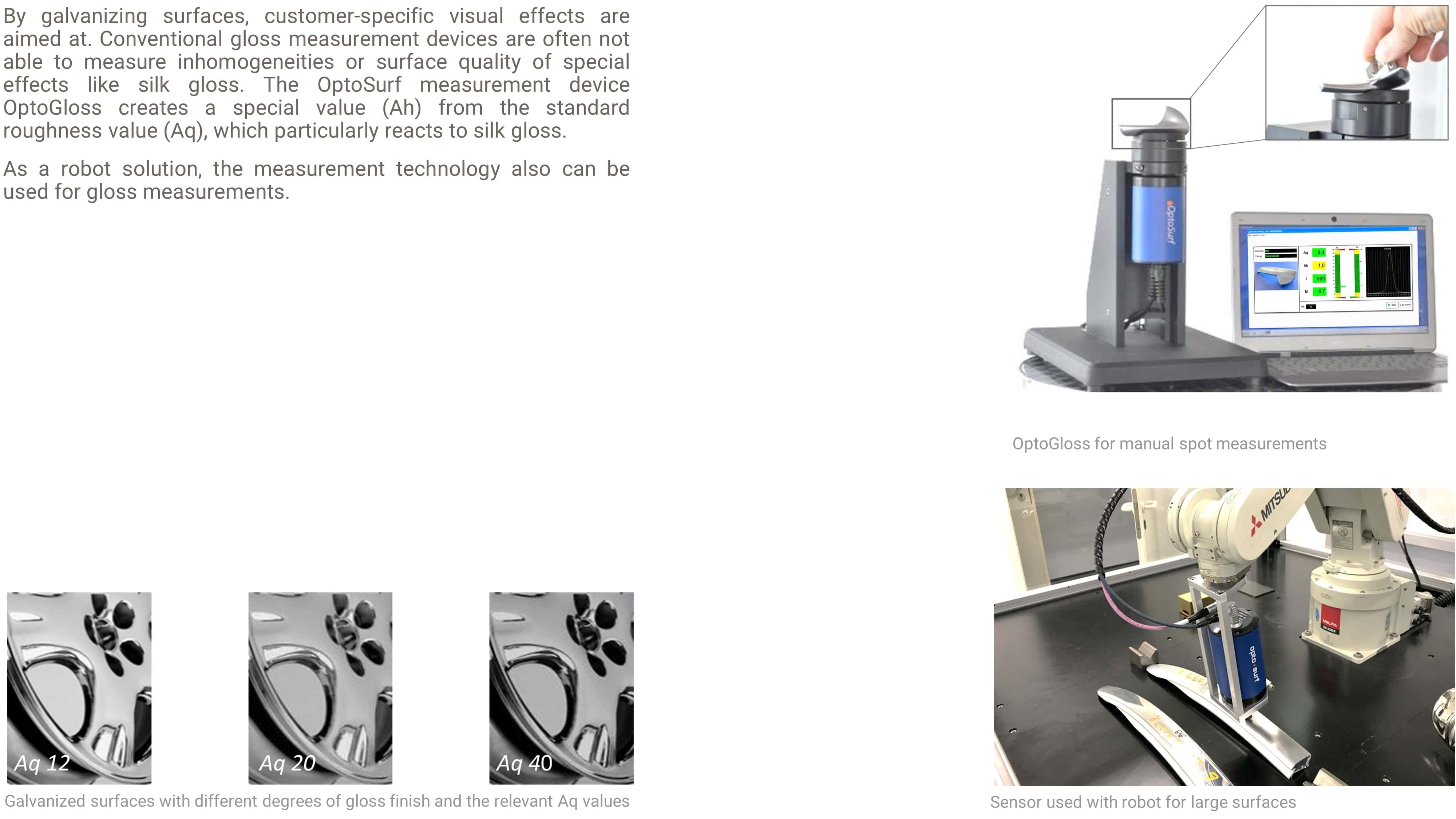

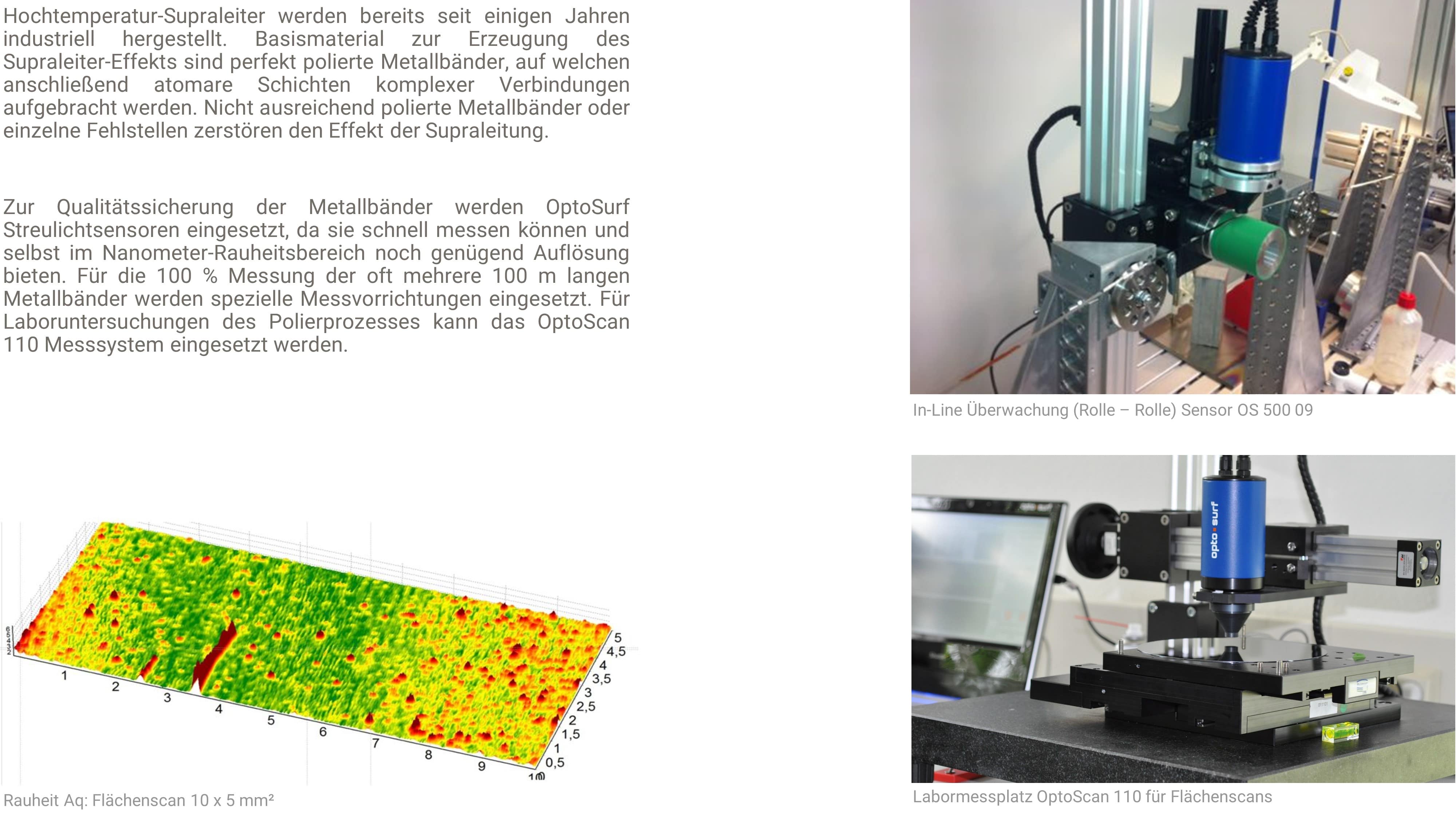

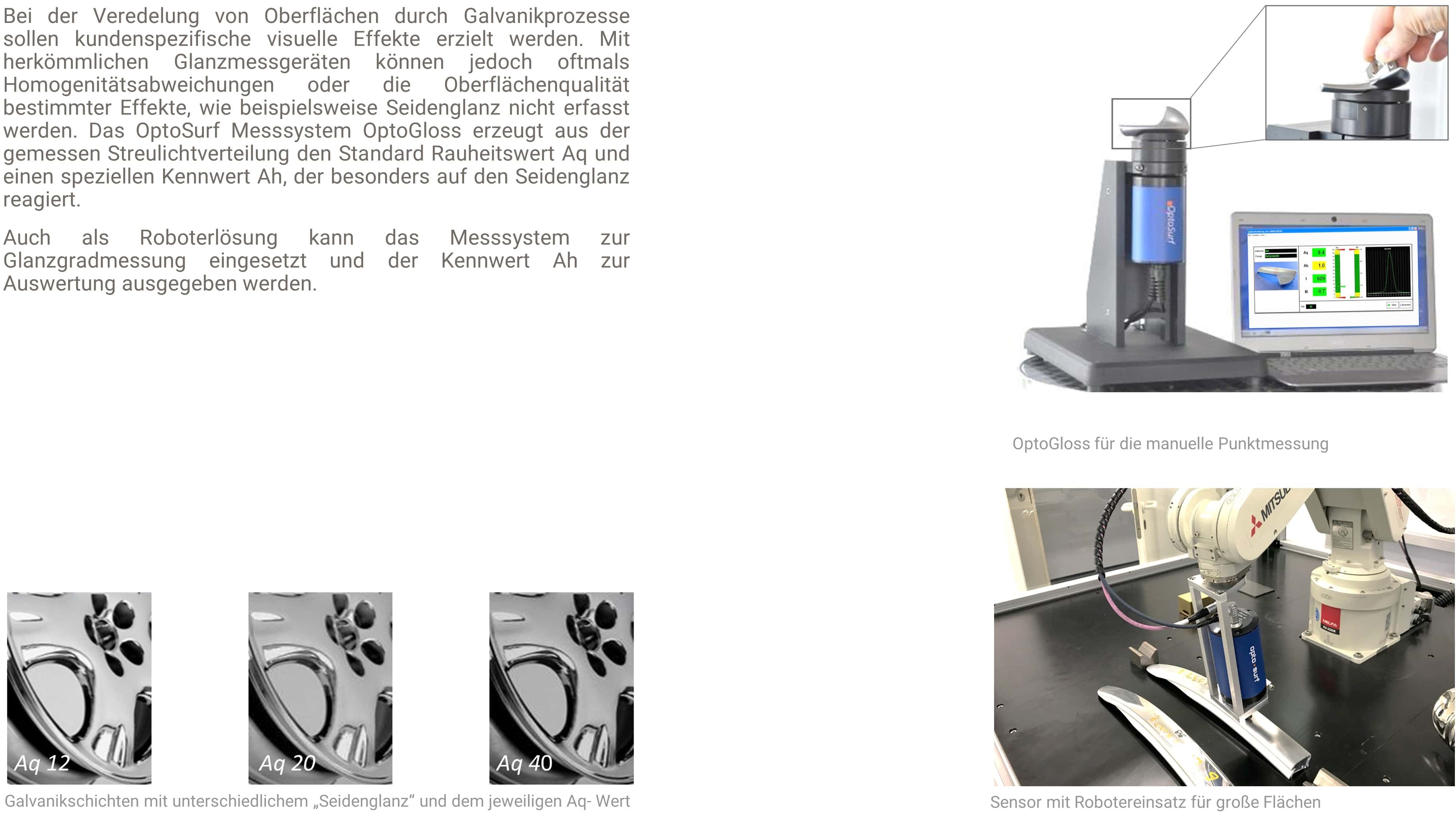

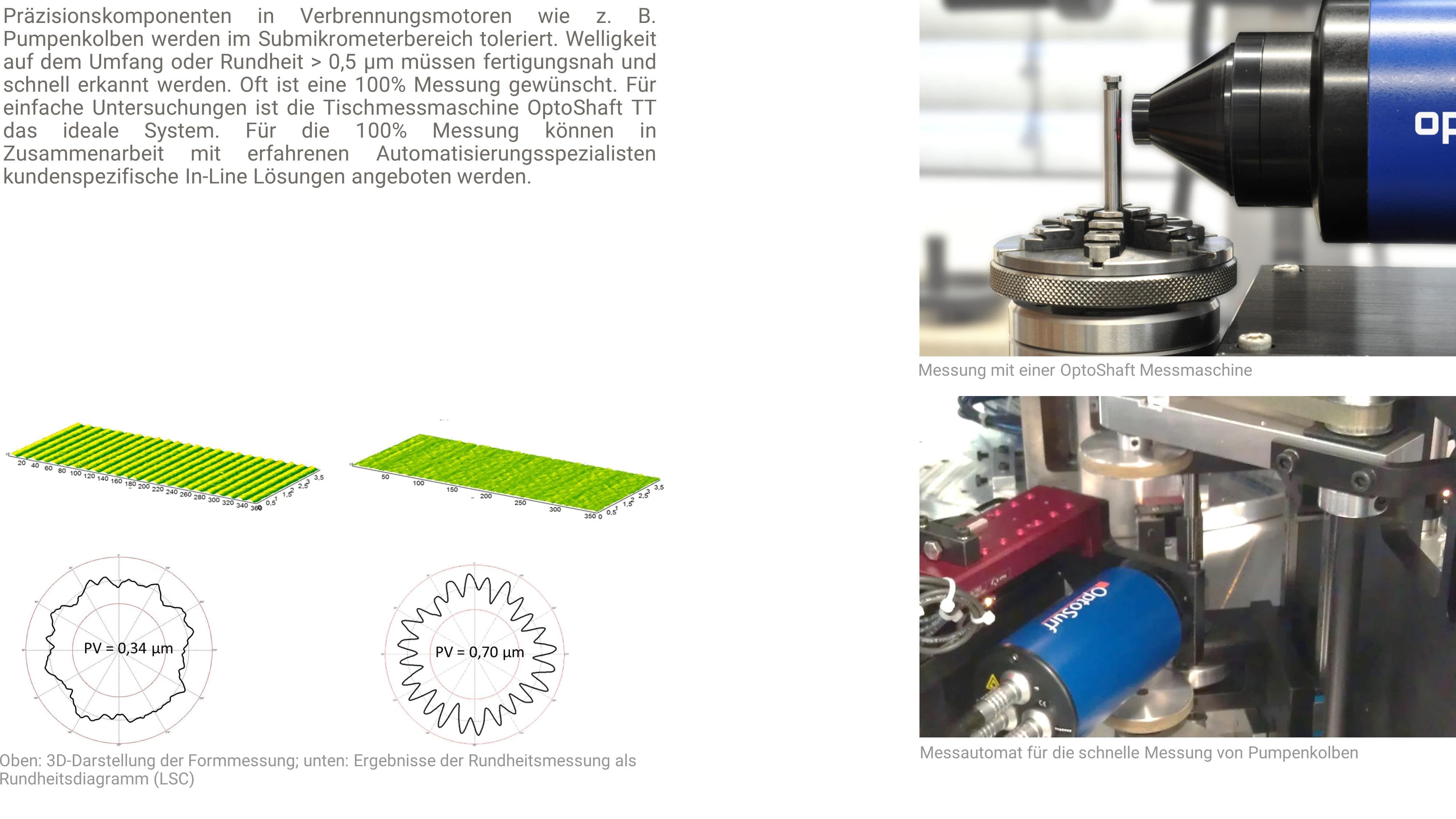

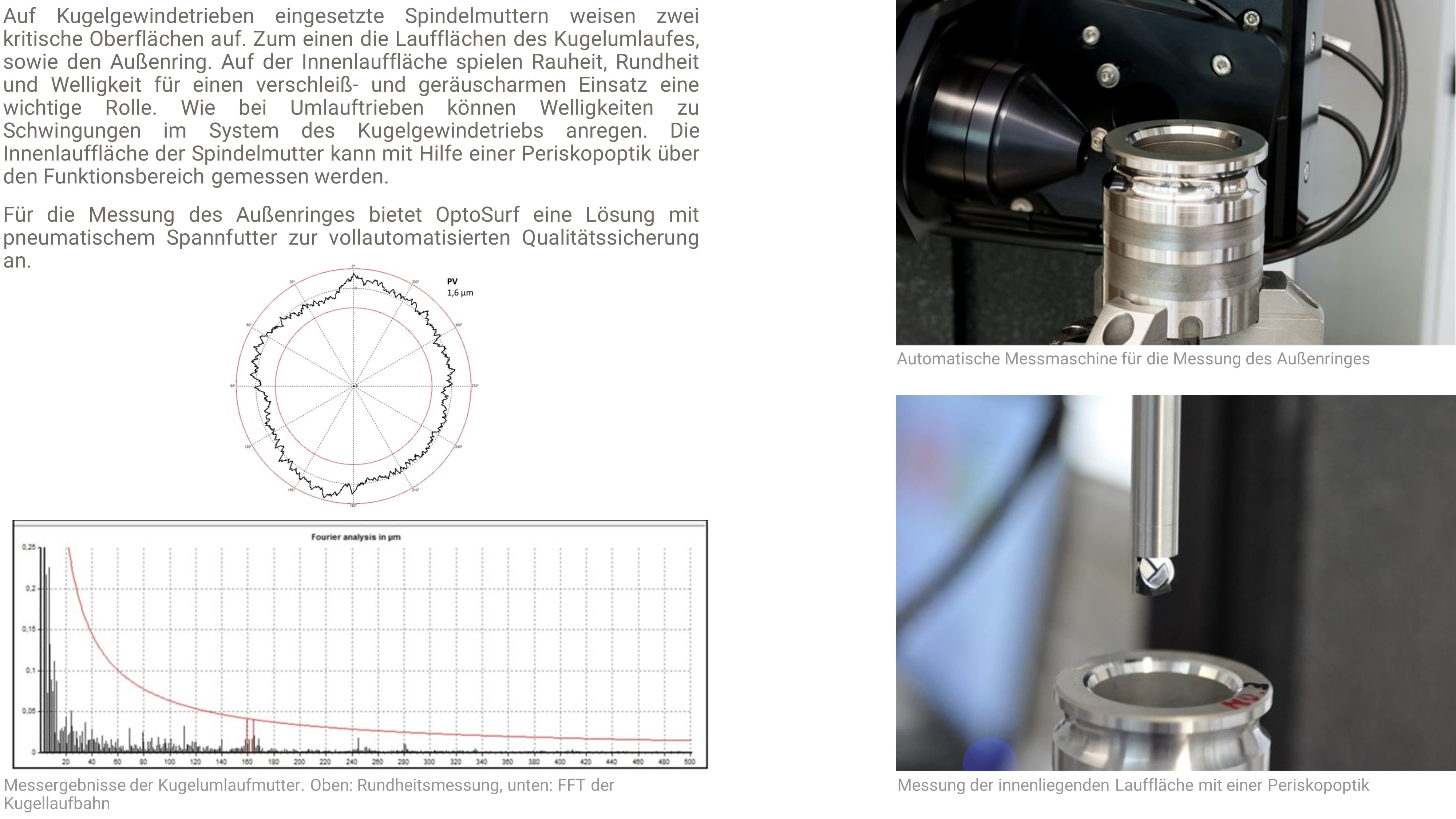

Modern and highly precise robot systems are a main component for successfully implemented process automation projects. The sensor’s lack of sensitivity allows finely machined surfaces to be measured in the submicrometer range using a robot arm. This is mounted directly on the mounting plate and all six axes can be used. With this unique combination, large parts, sometimes even with complex geometries, are measurable.

The measurement program is defined and saved in the OptoSurf software, which connects to a robot software interface. To start a measurement, a trigger signal is used.